Peter Insole

Western Thunderer

After the trauma of the transfers, (albeit happily resolved in the end) and a further delay on progress with the "little engine" due to a bout of illness, that is also sufficiently settled now, I fancied a brief break and something of a diversion on the workbench. Motivation came from both a promise to a friend, and something desirable that had played yet another influential part of my own childhood. The 7mm scale object, while appearing to be simple and straightforward was, I feared, likely to be a bit of a brain scrambler? Something that turned out to be quite so!

A common problem, and good reason why there are so few examples modelled is a notable, and apparently total lack of available drawings from any predictable, or at least obvious sources. I have managed to collect a lot of photographic images, and have acquired copies of various and vital principal dimensions, so that was excuse enough to have a go?!

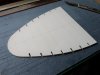

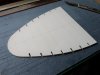

It was clear that a basic prototype would have to be measured out, drawn and built up in order to be able to visually check the subtleties of the design before committing to cutting any plastic.

That trusty old fashioned mountboard and paper would do perfectly...

I could not be at all sure that any of these tricky curves and angles would fit together, let alone remotely align on the next section to be constructed.

I added a non prototypical strip of pine to act as a spine for rigidity in what was a rather flimsy structure at this stage. The final model will have an extensively ribbed and boxed up double skin "Ceiling" to hopefully achieve the same effect.

OK., it can be a mystery no more, as the appearing shape should be familiar to anyone who was either born or raised near, had relatives living in the area, or had ever travelled to see to the old London river?!

Fortunately, and perhaps rather more amazingly, the curvy bits did more or less fit - and look pretty much right so far as a bonus! The real fun - and some surprises were about to start however.

More of that later though!

Pete.

A common problem, and good reason why there are so few examples modelled is a notable, and apparently total lack of available drawings from any predictable, or at least obvious sources. I have managed to collect a lot of photographic images, and have acquired copies of various and vital principal dimensions, so that was excuse enough to have a go?!

It was clear that a basic prototype would have to be measured out, drawn and built up in order to be able to visually check the subtleties of the design before committing to cutting any plastic.

That trusty old fashioned mountboard and paper would do perfectly...

I could not be at all sure that any of these tricky curves and angles would fit together, let alone remotely align on the next section to be constructed.

I added a non prototypical strip of pine to act as a spine for rigidity in what was a rather flimsy structure at this stage. The final model will have an extensively ribbed and boxed up double skin "Ceiling" to hopefully achieve the same effect.

OK., it can be a mystery no more, as the appearing shape should be familiar to anyone who was either born or raised near, had relatives living in the area, or had ever travelled to see to the old London river?!

Fortunately, and perhaps rather more amazingly, the curvy bits did more or less fit - and look pretty much right so far as a bonus! The real fun - and some surprises were about to start however.

More of that later though!

Pete.

It came as rather a surprise after all the complaints about Thames Water releasing sewerage in to the rivers feeding the Thames.)

It came as rather a surprise after all the complaints about Thames Water releasing sewerage in to the rivers feeding the Thames.)