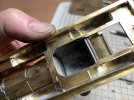

I've built the body and mostly built the chassis. So far it's gone OK with only a headache over the inside motion which is now working OK.

I've got to the stage to fit the outside frames and brake gear etc. and realised that there's no way to remove the wheels or motor when they're fitted. This will obviously be a pain for painting and maintenance when required.

Has anyone built this kit with the wheels removable? Is it possible to fit the outside frames to the body without compromising the chassis fittings?

Kev

I've got to the stage to fit the outside frames and brake gear etc. and realised that there's no way to remove the wheels or motor when they're fitted. This will obviously be a pain for painting and maintenance when required.

Has anyone built this kit with the wheels removable? Is it possible to fit the outside frames to the body without compromising the chassis fittings?

Kev

I'm debating whether to try to draw one and have it 3d printed, or see if I can get one out of Sanspareil. Mickoo's thread is inspiring me to have a go at 3D printing

I'm debating whether to try to draw one and have it 3d printed, or see if I can get one out of Sanspareil. Mickoo's thread is inspiring me to have a go at 3D printing