You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Mickoo's Commercial Workbench

- Thread starter mickoo

- Start date

mickoo

Western Thunderer

Seems to be more often that not these daysIt's turning into a very nice scratchbuilt loco.......

mickoo

Western Thunderer

Taking a break from the Garratt and it's back to the Masterpiece Princess Coronation.

The plan was to do all new etched cab, so grabbing the old parts I sallied forth in CAD, it soon became apparent that the bits from the model were so distorted that measuring would be next to useless, grabbing the works drawings showed other measurement tweaks would be needed, nothing much, just a smidge here and there.

Problem is a smidge is make or break when getting bit to fits something already made, you end up over extending the etch edges and filing back to suit where it touches.......if you're going to do all that then you might as well roll your own.

Out with the crayons and sharp adult tools a new cab front was worked up, it fits the model well, still one or two gaps to iron out but those will go once the whole lot is lowered about 0.4 mm.

It's much easier to trim and work on the new front with it attached to the roof, I got pretty close on it's own but it keeps flexing and you never know if you're taking material off that doesn't need it.

Once the fit is right and all square then I'll tend to the cab window top edges, they're just a basic angle until I know the roof is all square and in the right place, then I'll match that slope and make the two parallel.

I'll do an inner core skin, one that holds the seats and window frames, then ponder the final outer skin, I may still opt for an etch but I do have a Finney7 kit of my own so I might filch the sides and see if they fit or not, then worry about getting new etches for that at some point in the future.

I'll also scratch build the rear wall as well and that'll allow the cab turn in's and doors to be fitted up.

The plan was to do all new etched cab, so grabbing the old parts I sallied forth in CAD, it soon became apparent that the bits from the model were so distorted that measuring would be next to useless, grabbing the works drawings showed other measurement tweaks would be needed, nothing much, just a smidge here and there.

Problem is a smidge is make or break when getting bit to fits something already made, you end up over extending the etch edges and filing back to suit where it touches.......if you're going to do all that then you might as well roll your own.

Out with the crayons and sharp adult tools a new cab front was worked up, it fits the model well, still one or two gaps to iron out but those will go once the whole lot is lowered about 0.4 mm.

It's much easier to trim and work on the new front with it attached to the roof, I got pretty close on it's own but it keeps flexing and you never know if you're taking material off that doesn't need it.

Once the fit is right and all square then I'll tend to the cab window top edges, they're just a basic angle until I know the roof is all square and in the right place, then I'll match that slope and make the two parallel.

I'll do an inner core skin, one that holds the seats and window frames, then ponder the final outer skin, I may still opt for an etch but I do have a Finney7 kit of my own so I might filch the sides and see if they fit or not, then worry about getting new etches for that at some point in the future.

I'll also scratch build the rear wall as well and that'll allow the cab turn in's and doors to be fitted up.

mickoo

Western Thunderer

Picked up from paint yesterday and a quick reassembly, still need to add the glazing and touch up a few nicks here and there, it's going for DCC and weathering so not overly concerned about the odd scuff.

Back ground info for those not familiar from a few years back. The client bought it 2nd hand at a show for a good price and it only needed a cab roof. It was already painted but not really that well so it was decided to strip the paint anyway and apply all new, that's when the underlying work was revealed.

The decision was made to rebuild and it was accepted it'd never be perfect like a new build. The whole model was striped back down to individual pieces and all cleaned up, where etches were damaged then replacements were drawn, new coupling rods were required as well.

The kit didn't replicate the top bunker sheeting quite right, there may be engines matching the kit but I couldn't find any pictorial evidence and 6403 isn't one of them.

The changes are quite small and simple to do, the firebox top protrudes above the sheeting slightly and the chimney base should be below the sheeting, a small gap is often visible between the sheeting edge and chimney base.

A new etch cover plate solved all that and it was then just a simple case of putting it all back together.

It's not perfect by a long margin, but from where it started, it's an improvement and it has been saved from the metal scrap bin.

Back ground info for those not familiar from a few years back. The client bought it 2nd hand at a show for a good price and it only needed a cab roof. It was already painted but not really that well so it was decided to strip the paint anyway and apply all new, that's when the underlying work was revealed.

The decision was made to rebuild and it was accepted it'd never be perfect like a new build. The whole model was striped back down to individual pieces and all cleaned up, where etches were damaged then replacements were drawn, new coupling rods were required as well.

The kit didn't replicate the top bunker sheeting quite right, there may be engines matching the kit but I couldn't find any pictorial evidence and 6403 isn't one of them.

The changes are quite small and simple to do, the firebox top protrudes above the sheeting slightly and the chimney base should be below the sheeting, a small gap is often visible between the sheeting edge and chimney base.

A new etch cover plate solved all that and it was then just a simple case of putting it all back together.

It's not perfect by a long margin, but from where it started, it's an improvement and it has been saved from the metal scrap bin.

simond

Western Thunderer

That's what I call modelling, starting all over again. Lovely job and the wheels are a nice profile too. Always had a soft spot for the 64xx/74xx, but the 7mm ready-to-run model was too darn noisy, which I put down to the belt drive.

mine isn't. maybe I'm just lucky?

LarryG

Western Thunderer

I had three over time from the same source, so maybe I was just unlucky or there existed a conspiracymine isn't. maybe I'm just lucky?

. They all sounded exactly the same with the whine clearly audible above the DCC steam sounds.

. They all sounded exactly the same with the whine clearly audible above the DCC steam sounds.It didn't bother my friends, but I do have keen hearing.

daifly

Western Thunderer

Mine is an original Lionheart version. Perhaps the classic version is a better built loco as mine, too, is a beautifully quiet runner.mine isn't. maybe I'm just lucky?

Dave

Focalplane

Western Thunderer

I think that once you can hear an unwanted background noise it's very hard to dismiss it. For the same reason I dislike high ambient noise places as I can't hear the conversation I actually want to hear! This may be an age thing but a long time ago I was asked a question on an oil rig and, being young, answered "yes" because I wasn't sure of what I heard. They stopped drilling! One of life's lessons!

Last edited:

mickoo

Western Thunderer

Quick change of tack, it was going to take forever to cut all the Garratt brake gear out and fit, as well as scratch build the motion brackets. The only answer was to etch and those bits plus the Princess Coronation cab sides are now off at the etchers.

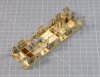

To fill the few weeks until the etches return I'm going to bash on with this, a Finney7 Duke and 2500G tender. It's a simple out of the box build with inside motion so I'm not expecting a long drawn out build.

I need to work fast and keep the brass as clean as I can as the photos will be used to revamp the instructions set. A couple of days find's most of the tender chassis completed, hopefully all done tomorrow and then move upward to the body.

As it stands the kit has you build the tender chassis with the wheels locked into place, not overly happy with that as the wheels need lining. I did plan to work up some sort of dummy inner chassis that could be dropped in and out but decided to use what I had to save time.

If you're really careful you can just spring the chassis sides apart and ease out the wheels and top hat bearings, the leading and intermediate for part of a rocking beam system so it takes a little care to get it all in place and flexible. The trailing axle is rigid so those bearings can be soldered into place. I also added packing washers to limit side play and prevent shorting on the white metal brake shoes.

The final modification is on the brake rigging, it traps in the axles so it needs some way to be semi movable. In the end I built it all up rigid and then slit the cross tie rods between the pull rods and droppers. The front end cranks are loose so the pull rods can swing up out of the way. Small pieces of tube will be fitted to the cross tie rods and these clip into the stubs on the droppers, at the moment only the rear axle has the little bits of tube on.

There's two slack adjusters up front and they shouldn't be joined together with a cross tie, but I have to keep the front end cranks the correct distance apart and give it all a bit of strength during the build. I'll probably cut that last rod after paint to leave the correct individual pins in each slack adjuster.

To fill the few weeks until the etches return I'm going to bash on with this, a Finney7 Duke and 2500G tender. It's a simple out of the box build with inside motion so I'm not expecting a long drawn out build.

I need to work fast and keep the brass as clean as I can as the photos will be used to revamp the instructions set. A couple of days find's most of the tender chassis completed, hopefully all done tomorrow and then move upward to the body.

As it stands the kit has you build the tender chassis with the wheels locked into place, not overly happy with that as the wheels need lining. I did plan to work up some sort of dummy inner chassis that could be dropped in and out but decided to use what I had to save time.

If you're really careful you can just spring the chassis sides apart and ease out the wheels and top hat bearings, the leading and intermediate for part of a rocking beam system so it takes a little care to get it all in place and flexible. The trailing axle is rigid so those bearings can be soldered into place. I also added packing washers to limit side play and prevent shorting on the white metal brake shoes.

The final modification is on the brake rigging, it traps in the axles so it needs some way to be semi movable. In the end I built it all up rigid and then slit the cross tie rods between the pull rods and droppers. The front end cranks are loose so the pull rods can swing up out of the way. Small pieces of tube will be fitted to the cross tie rods and these clip into the stubs on the droppers, at the moment only the rear axle has the little bits of tube on.

There's two slack adjusters up front and they shouldn't be joined together with a cross tie, but I have to keep the front end cranks the correct distance apart and give it all a bit of strength during the build. I'll probably cut that last rod after paint to leave the correct individual pins in each slack adjuster.

Last edited:

mickoo

Western Thunderer

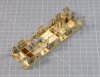

Bimbling along nicely now with the Finney7 Duke & 2500G tender.

As is my want a few tweaks to suit my build methodology, the tank sides are half etched with a flat beading along the top and front edge, for the coal rail version you need to remove the front edge, cut the inset section out and then add new flat beading at the inset.

It took nearly as long to write that as it did to cut a whole new tank side and rear sans flat beading, next I'll add the correct D profile beading and reinstate the strengthening strap along the base.

One thing I have found is that when trying to form the flair, half etch beading can make a crease in the platework, probably just me being ham fisted, I find not having the beading there helps me form a better/smoother flair. The D Shaped beading does also bind the top of the corner fingers better as well.

The only other change was the footplate valances, these are also half etched and very thin, mine were over etched so the rivet detail was a bit light and at one end the depth reduced due to the over etching. Simple to just cut new ones from brass strip, punch the rivets and fit.

I doubt I'll finish it tomorrow but end of play on Weds would suit me schedule and planning.

As is my want a few tweaks to suit my build methodology, the tank sides are half etched with a flat beading along the top and front edge, for the coal rail version you need to remove the front edge, cut the inset section out and then add new flat beading at the inset.

It took nearly as long to write that as it did to cut a whole new tank side and rear sans flat beading, next I'll add the correct D profile beading and reinstate the strengthening strap along the base.

One thing I have found is that when trying to form the flair, half etch beading can make a crease in the platework, probably just me being ham fisted, I find not having the beading there helps me form a better/smoother flair. The D Shaped beading does also bind the top of the corner fingers better as well.

The only other change was the footplate valances, these are also half etched and very thin, mine were over etched so the rivet detail was a bit light and at one end the depth reduced due to the over etching. Simple to just cut new ones from brass strip, punch the rivets and fit.

I doubt I'll finish it tomorrow but end of play on Weds would suit me schedule and planning.

michael mott

Western Thunderer

Such lovely clean work!

michael

michael

mickoo

Western Thunderer

Thanks, it's only this 'extra' clean for the instruction photos, once they are done it'll be allowed to slowly tarnish before going to paint.Such lovely clean work!

michael

I find you get about two weeks before brass starts to lose it's shine, mind that depends on how often you clean it or how dirty it gets before hand, fingers are the worst, that greasy residue is quite hard to get off and mixed with flux can be quite a witch to deal with.

On this build it's not yet been touched by bare fingers, all nitrile glove work and it seems to have kept it much cleaner for much longer.

michael mott

Western Thunderer

Why will it be allowed to tarnish? will this have a positive effect on the painting?

Michael

Michael