mick Stearne

Member

Hi Everybody

Just joined the forum I have just started this build and wondered if any of you have built an easybuild kit I found the progress is very slow but I think i am getting there, I have also made a few changes i will upload some photoe's as i progress,

.

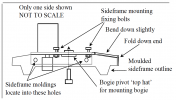

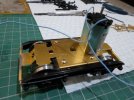

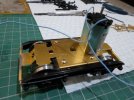

some photoes of the bogies to start with,

I purchased some slater's plunger pickups to mount under the bogies by folding up a channel section in brass.and mounting them under the chassis.

This craven unit is for my o gauge layout which is modelled to the stour valley line at Sudbury and Long melford in suffolk which is where i grew up and often travelled on a class 105 or a derby lightweight.

Mick

Just joined the forum I have just started this build and wondered if any of you have built an easybuild kit I found the progress is very slow but I think i am getting there, I have also made a few changes i will upload some photoe's as i progress,

.

some photoes of the bogies to start with,

I purchased some slater's plunger pickups to mount under the bogies by folding up a channel section in brass.and mounting them under the chassis.

This craven unit is for my o gauge layout which is modelled to the stour valley line at Sudbury and Long melford in suffolk which is where i grew up and often travelled on a class 105 or a derby lightweight.

Mick

Last edited: