Heather Kay

Western Thunderer

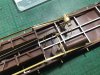

Thoughts are beginning to turn to sorting out the interiors of the coaches. I have a cunning plan I’m keen to tryout.

I have thoroughly confused myself today, trying to pin down what sort of things were going on inside Maunsell coaches by the 1960s. I assume the interior panel work would have pretty much remained as built, but I can’t believe seating would have survived some three decades in service without being recovered at some point.

The Southern Railway Email Group web site has some useful colour photos of the Maunsells preserved on the - I think - the Bluebell Railway. The vehicles are preserved in Southern Railway livery, and appear to have had interiors restored to match the original build. The interior shots of first and third class compartments are down the page linked here.

As it happens, I found a Flickr album of various seating moquette swatches. Some are suitable for early SR and BR (SR), and you will find the Bluebell Railway moquettes in the set. My question, though, is which of the numerous patterns is most likely to have been used when refurbishing these coaches after the Second World War?

I’m sure one of you Southern fans will be able to advise. Ta.

I have thoroughly confused myself today, trying to pin down what sort of things were going on inside Maunsell coaches by the 1960s. I assume the interior panel work would have pretty much remained as built, but I can’t believe seating would have survived some three decades in service without being recovered at some point.

The Southern Railway Email Group web site has some useful colour photos of the Maunsells preserved on the - I think - the Bluebell Railway. The vehicles are preserved in Southern Railway livery, and appear to have had interiors restored to match the original build. The interior shots of first and third class compartments are down the page linked here.

As it happens, I found a Flickr album of various seating moquette swatches. Some are suitable for early SR and BR (SR), and you will find the Bluebell Railway moquettes in the set. My question, though, is which of the numerous patterns is most likely to have been used when refurbishing these coaches after the Second World War?

I’m sure one of you Southern fans will be able to advise. Ta.

- so I think embedding them in a pool of epoxy resin might be the long term solution. Still, proof of concept and all that, it does actually work and holds the roof in place. I will need to add guide strips to ensure the roof remains aligned correctly, but now I just have to repeat the method for all the coaches.

- so I think embedding them in a pool of epoxy resin might be the long term solution. Still, proof of concept and all that, it does actually work and holds the roof in place. I will need to add guide strips to ensure the roof remains aligned correctly, but now I just have to repeat the method for all the coaches.

)

)