Heather Kay

Western Thunderer

I must admit to have succumbed to feelings of inadequacy, caused by some superb and speedy modelling skills elsewhere on WT. When I see fantastic models being completed at a fair rate of knots, I begin to wonder what it is I do all day that takes me so long!

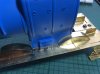

I found some brass pins just the perfect size to be fettled into the cylinder cover knobs. I glued some 0.8mm diameter hex nuts on the block where I'd marked the row with slight rivets. You'll never see the difference, but I hope the variation is size will be noticeable. Then I removed and tidied up the remains of the etched lamp brackets before fitting the cast versions. The jury is out on whether to bother with the storage brackets up by the firebox. Next, I tried to figure out how the sanding operating levers went together.

The rod that passes through the cylinder cover on the real thing does exactly the same in the kit. It doesn't have to, but it helps to ensure the fireman's side operating mechanism sits at the same angle as the gubbins on the driver's side. Finally, sandbox lids. There aren't many running plate details to go, just grab rails, so I may as well press on with the hanging bars and steps.

I'm sort of holding back on the underframe, because I have an ABC gearbox and motor on order which I shall collect at Telford in a couple of weeks.

So, to sum up most of a week on this build: cab detailing is pretty much complete; running plate upperworks almost done; the chimney and safety valve bonnet have been fettled and polished as necessary. I feel I should have achieved much more than that, but there you are.

I found some brass pins just the perfect size to be fettled into the cylinder cover knobs. I glued some 0.8mm diameter hex nuts on the block where I'd marked the row with slight rivets. You'll never see the difference, but I hope the variation is size will be noticeable. Then I removed and tidied up the remains of the etched lamp brackets before fitting the cast versions. The jury is out on whether to bother with the storage brackets up by the firebox. Next, I tried to figure out how the sanding operating levers went together.

The rod that passes through the cylinder cover on the real thing does exactly the same in the kit. It doesn't have to, but it helps to ensure the fireman's side operating mechanism sits at the same angle as the gubbins on the driver's side. Finally, sandbox lids. There aren't many running plate details to go, just grab rails, so I may as well press on with the hanging bars and steps.

I'm sort of holding back on the underframe, because I have an ABC gearbox and motor on order which I shall collect at Telford in a couple of weeks.

So, to sum up most of a week on this build: cab detailing is pretty much complete; running plate upperworks almost done; the chimney and safety valve bonnet have been fettled and polished as necessary. I feel I should have achieved much more than that, but there you are.

.

.

. I also spent a while reconciling the instructions with what was actually in the box as regards hornguides and axlebox bearings. Let's just say the test build for the instructions used different parts, so I'm left wondering how to make a working suspension system with what I have.

. I also spent a while reconciling the instructions with what was actually in the box as regards hornguides and axlebox bearings. Let's just say the test build for the instructions used different parts, so I'm left wondering how to make a working suspension system with what I have.