mickoo

Western Thunderer

Nice when you get a bargainI find it very easy to get sidetracked and diverted from the job in hand in this hobby.

So this Accucraft 1:20.3 scale K27 appeared on UK Ebay at what I thought was a very reasonable Buy it Now price. However the details given were very brief and the photos were all taken from one side so didn't show all of the loco. According to the description it had paint damage to the cab roof and other areas, the cab roof paint damage was obvious, the "other areas" not so, but it was covered in a layer of dirt so who knows what was underneath. It was said to have been purchased new 25 years ago, test run but never run on a track and stored ever since. It had obviously been stored exposed in a shed or garage to collect so much dirt. I did get more photos from the seller taken from the other side and the information that it had a sound system of some sort.

According to the Brass Guide these electric versions were produced in 2000 and 2001, and live steam versions in 2003 and 2006.

However as the saying goes "nothing ventured nothing gained" or perhaps more appropriate "a fool and his money......", with several watchers and nearly a month to go I didn't bother with the make an offer option but bought at the Buy it Now price. Against better judgement I arranged for it to be delivered, but fortunately it was well packed and appeared to have suffered no damage in transit. The only items that appear to be missing are one of the tender re-railing ramps and the air hoses at each end. The loco and tender needed partly dismantling and two thorough washes to remove all the muck. The cab roof had traces of green oxidation as well as a small damaged area of paintwork so it was completely stripped down to bare metal and repainted with black self etch primer and satin black. The cab had to be removed to clean the muck off the firebox and backhead, so that made the roof painting a lot easier, these locos are very heavy and awkward to handle complete. Elsewhere there were traces of green oxidation on and around some of the fixing screws. These are hex headed 1.6mm or 2mm dia. brass which are chemically blackened rather than painted. So they could be removed, cleaned up, any residue on the paintwork around the screw cleaned off and the screws replaced and painted. Otherwise any other paintwork required was just touching up small areas. The number decals on the left hand cab side have partly flaked off, so replacement decals have been ordered. The wheels show no sign of wear, so it seems to have had little use or maybe only test run as the Ebay description. I've got no live rail 45mm track, but lifted off its drivers and run on 12 volts its smooth running and very quiet.

One potential problem with these models is the front pilot beam. The loco is very heavy and the only way of lifting at the front end without some special kind of lifting device is by placing your hand under the pilot. This can tend to bend the front of the sheet metal pilot beam and break the joint between the front and the top. There were signs that this joint was starting to split, so its been re-soldered at the rear and short lengths of angle added at the rear to reinforce the joint. The black paint Accucraft use will stand soldering with a blowtorch without any ill effects, you just have to watch other items don't drop off in the process. A similar loco for sale on US Ebay recently had suffered the same problem and the item description stated "The pilot attachment has been repaired, and while still attached could use a bit of attention to fully correct". The bit of attention was rather an understatement as despite the botched attempt at repair the pilot beam had come apart completely.

The sound system is by Sierra, an early Soundtraxx system I believe, and it was entirely self contained in the tender. The only electrical connection between the tender and loco being via the drawbar for live rail operation. The sound system was fed by a battery and also sprung plunger pickups on the tender wheels, chuff synchronisation being by two small magnets on the back of a tender wheel. I did start to figure out what wire went where and exactly how it worked, but in the event just ripped the lot out including the massive speaker, as the tender had to be completely dismantled to get rid of all the muck. Eventually the loco will be converted to RC/battery dead rail operation using the same sound system in the C16 I described earlier in this thread. I might retain the chuff synchronisation on the tender wheel if it works, although it won't be exact as the tender wheels are not exactly half the size of the drivers, 26" prototype tender against 40" of the driving wheels.

View attachment 149227

View attachment 149228

View attachment 149229

View attachment 149230

View attachment 149231

View attachment 149232

View attachment 149233

View attachment 149234

So overall the conclusion is

Looks just the ticket

Mountain Train

Mountain Train BNSF westbound at Rock Creek

BNSF westbound at Rock Creek

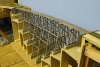

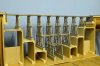

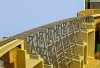

. The guard rails are spiked to every third tie and have only two bolt fishplates. The dark brown colour of the rails is temporary and they will be painted a lighter red/brown rust colour later. I've omitted the water barrel platforms, not all trestles of this length had them, if I provided them the length would probably only justify one in the middle, if it was on the viewing side it would obstruct the view of the train, if it was on the other side it would produce an awkward shadow on the backscene, and its a damn sight easier to leave them out !

. The guard rails are spiked to every third tie and have only two bolt fishplates. The dark brown colour of the rails is temporary and they will be painted a lighter red/brown rust colour later. I've omitted the water barrel platforms, not all trestles of this length had them, if I provided them the length would probably only justify one in the middle, if it was on the viewing side it would obstruct the view of the train, if it was on the other side it would produce an awkward shadow on the backscene, and its a damn sight easier to leave them out !