You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm US model dabblings

- Thread starter Jordan

- Start date

Brian Daniels

Western Thunderer

mickoo

Western Thunderer

At least you have somewhere to run them  I don't as yet and that's something I really must do something about.

I don't as yet and that's something I really must do something about.

As far as I know, Sunset didn't do cowl 45's? I could be wrong. I do keep seeing KTM - US Hobbies 45's on Ebay now and again, they go for a good cheap price but they seem to have missed the mark with the bonnet and windscreens. The KTM model has a distinct ridge in the middle (your's do look like KTM and it does look less on your painted ones) which is easily seen in bare brass, in addition it is mounted a touch too low.

I measured the difference of the ridge as best I could with reference to the windscreen base and it's no more than 5 mm higher in the middle. The LH screen (RH in picture) is not a good reference on #95 as the metal has corroded badly and forced the gasket out of alignment.

Given their relative low price, which is a shame for their origination, I am tempted to bag one and modify because the rest of the engine looks reasonably good although I haven't picked one apart in detail, I have kinda not bothered to look past the nose issue in great depth.

Still, owning something that's 95% accurate is better than not owning something that's 100% accurate

Cowl 45's look good in red and blue warbonnet, even the aborted merger kodachrome scheme looked good on them, not so smart in Amtrak or BN green mind.

I don't as yet and that's something I really must do something about.

I don't as yet and that's something I really must do something about.As far as I know, Sunset didn't do cowl 45's? I could be wrong. I do keep seeing KTM - US Hobbies 45's on Ebay now and again, they go for a good cheap price but they seem to have missed the mark with the bonnet and windscreens. The KTM model has a distinct ridge in the middle (your's do look like KTM and it does look less on your painted ones) which is easily seen in bare brass, in addition it is mounted a touch too low.

I measured the difference of the ridge as best I could with reference to the windscreen base and it's no more than 5 mm higher in the middle. The LH screen (RH in picture) is not a good reference on #95 as the metal has corroded badly and forced the gasket out of alignment.

Given their relative low price, which is a shame for their origination, I am tempted to bag one and modify because the rest of the engine looks reasonably good although I haven't picked one apart in detail, I have kinda not bothered to look past the nose issue in great depth.

Still, owning something that's 95% accurate is better than not owning something that's 100% accurate

Cowl 45's look good in red and blue warbonnet, even the aborted merger kodachrome scheme looked good on them, not so smart in Amtrak or BN green mind.

Brian Daniels

Western Thunderer

mickoo

Western Thunderer

Brian, nice  certainly looks like the KTM - U S hobbies version, I can't find any other brass ones....no doubt Phil will educate me shortly with his uncanny knowledge of US imported brass models

certainly looks like the KTM - U S hobbies version, I can't find any other brass ones....no doubt Phil will educate me shortly with his uncanny knowledge of US imported brass models

Other than checking all the grills and bodyside platework they do look like a good representation apart from the nose, the exaggerated ridge down the middle gives the peak at the front a rather pointed appearance and the side sheets should be a little higher.

These are copyright to their owners and displayed for information purposes.

The flatness of the nose top is seen better head on, there is a small ridge but it is barely visible, if KTM pulled up the bend where it goes from flat to angled, then the side bend between angled and vertical would move up as well and it'd be near perfect. They have captured the slight slope downward toward the front though.

The Cowl 45 cabs were near identical copies....may even have used the same jigs....as the DD40AX Centennials, later EMD would use a similar cab for it's GP60M models, the only difference there was the lack of forward slope, the top and bends are parallel with the rail head.

I think I've seen three go up for grabs on Ebay this year and I don't think any of them sold, which is a shame as with a little work they could be very nice.....seems like I've talked myself into one doesn't it

certainly looks like the KTM - U S hobbies version, I can't find any other brass ones....no doubt Phil will educate me shortly with his uncanny knowledge of US imported brass models

certainly looks like the KTM - U S hobbies version, I can't find any other brass ones....no doubt Phil will educate me shortly with his uncanny knowledge of US imported brass models

Other than checking all the grills and bodyside platework they do look like a good representation apart from the nose, the exaggerated ridge down the middle gives the peak at the front a rather pointed appearance and the side sheets should be a little higher.

These are copyright to their owners and displayed for information purposes.

The flatness of the nose top is seen better head on, there is a small ridge but it is barely visible, if KTM pulled up the bend where it goes from flat to angled, then the side bend between angled and vertical would move up as well and it'd be near perfect. They have captured the slight slope downward toward the front though.

The Cowl 45 cabs were near identical copies....may even have used the same jigs....as the DD40AX Centennials, later EMD would use a similar cab for it's GP60M models, the only difference there was the lack of forward slope, the top and bends are parallel with the rail head.

I think I've seen three go up for grabs on Ebay this year and I don't think any of them sold, which is a shame as with a little work they could be very nice.....seems like I've talked myself into one doesn't it

Scale7JB

Western Thunderer

Well it finally arrived today, pure exotic indulgent Railroad filth.

Impressive seven days door to door from the US, missed the men in grey too, I don't object to paying excisebut it's nice when one slips through

.

It's from the first batch OMI did, model is tagged as #7 of 53 in 1995, it looks like I payed for a second edition (plus some) from 2000 which is listed at about 150% more. I actually don't mind as this is well worth it to me.

The model is immaculate, there are a few paint flaws from the factory, and as is usual with Korean brass, some assembly issues, fit, soldering etc but these are minor niggles. It appears to be zero mileage as well so could be a show case queen and the storage box is in very good shape for 26 years old.

It doesn't fit any of my planned US modeling and the 1:1 engine is a small niche run from EMD, the SD75M didn't total many units as Railroads were not keen on the extra HP boosted from the SD70 prime mover.

ATSF 250 was the last engine ordered and delivered for ATSF, it may even have been delivered after the BNSF merger but carried ATSF logos.

The most important thing for me is the model will allow me to scale and cross reference for my SD70 model etchings, they say you should never copy a copy, but OMI are usually pretty good and If I don't know what the real ones measure at, then I won't know my model is wrong will I

View attachment 142017

View attachment 142018

View attachment 142019

View attachment 142020

View attachment 142021

View attachment 142022

Yep, filth!

JB.

Big Train James

Western Thunderer

For anybody interested, Sunset (via it's 3rd Rail subsidiary) has announced tentative plans to produce the f45 and/or the fp45. Others have suggested that they also do the sdp40f while they are at it, since they will ostensibly have the appropriate drive from the tunnel motors they have also announced.

It will undoubtedly be priced at twice the going rate for a KTM version, or more depending on reservations, but it will most likely be a more accurate model.

I would like to support 3rd rail by ordering some sd40-2's from them, but I can't get past their use of tank drives with the drive shafts coming out the ends of the fuel tank. It's old time technology at best. The models run well, they are single motor drives, but on locos without side skirting, and especially with shorter fuel tanks, the exposed drive shaft would be a real deal breaker for me. I wish I could get my hands on just the shells, but it doesn't work that way. And I'm not dropping $800 ish on a loco just to immediately deconstruct it, even if I could sell off the unused chassis.

It will undoubtedly be priced at twice the going rate for a KTM version, or more depending on reservations, but it will most likely be a more accurate model.

I would like to support 3rd rail by ordering some sd40-2's from them, but I can't get past their use of tank drives with the drive shafts coming out the ends of the fuel tank. It's old time technology at best. The models run well, they are single motor drives, but on locos without side skirting, and especially with shorter fuel tanks, the exposed drive shaft would be a real deal breaker for me. I wish I could get my hands on just the shells, but it doesn't work that way. And I'm not dropping $800 ish on a loco just to immediately deconstruct it, even if I could sell off the unused chassis.

Jordan

Mid-Western Thunderer

I do like that philosophy!!Still, owning something that's 95% accurate is better than not owning something that's 100% accurate

Mindyou, I'm not sure that even my best models reach 95% accuracy!!

mickoo

Western Thunderer

The values are arbitraryI do like that philosophy!!

Mind you, I'm not sure that even my best models reach 95% accuracy!!

and it's a spin off from the old saying 'a bird in the hand is better than two in the bush'.

and it's a spin off from the old saying 'a bird in the hand is better than two in the bush'.In more blunt terms, be thankful for what you have and not what you wish for, or as someone said to me the other week, manage your expectations.

I struggle mentally on a massive scale with how much detail to add, where and when, if I know, then it should be present, I hand wring over the smallest detail and the end result is often a big fat zero.

My engines have to tick certain strict self imposed boxes, yet elsewhere I completely care less, rolling stock and scenery are classic examples, my signal box could be Flemish bond, Belgium brick, red Leicester (think that's a cheese

) but the engine must have the correct lubricators and piping.

) but the engine must have the correct lubricators and piping.Just madness really.

One thing doing commercial work teaches you is that you have no control over what the client wishes, many just want shake the box builds which goes against my detail freak inside, yet, when they see the final model their joy is infectious.

So who's right, me for wanting more detail or them for being happy with much less, I'm beginning to think they are because they actually have something, where as I have very little.

I have four fifths of your GP38 spartan cab access doors btw, just trying to find time to run up a new etch with the last ones on. I may just send these and if you're happy, do the last one, if not then nothing lost.

mickoo

Western Thunderer

Sunset 3rd Rail is a middle ground for me, a market between RTR and imported brass, I'm not overly taken by their current Dash 9 model, though I see they are canvasing for a new model and batch. I do like the look of their ML-4000 mind and have held off so far.For anybody interested, Sunset (via it's 3rd Rail subsidiary) has announced tentative plans to produce the f45 and/or the fp45. Others have suggested that they also do the sdp40f while they are at it, since they will ostensibly have the appropriate drive from the tunnel motors they have also announced.

It will undoubtedly be priced at twice the going rate for a KTM version, or more depending on reservations, but it will most likely be a more accurate model.

I would like to support 3rd rail by ordering some sd40-2's from them, but I can't get past their use of tank drives with the drive shafts coming out the ends of the fuel tank. It's old time technology at best. The models run well, they are single motor drives, but on locos without side skirting, and especially with shorter fuel tanks, the exposed drive shaft would be a real deal breaker for me. I wish I could get my hands on just the shells, but it doesn't work that way. And I'm not dropping $800 ish on a loco just to immediately deconstruct it, even if I could sell off the unused chassis.

The tank drive doesn't seem to niggle me as much as chain drives, one of the brass import brands uses that and it just goes against my engineering sensibilities. Another I've seen is a long thin geared drive, more like a chainsaw blade in appearance with the gears contained inside, a recent brass Centennial and DD35 both had that as well as a juice jack, can't remember the exact railroad model, possibly PRR FF2 but it may also have been chain drive.

I do like Overlands axle type gearboxes and the SD75M is a big step forward in that there is no tank drive shaft, somehow it goes up into the shell somewhere near the truck pivot point and I'm in no mood to strip it down to find out how.

As an aside I saw someones Lionel k-line SD75M/I pimped out, more scale wheels, 2 rail, fuel tank fed a diet of donuts and coca cola, fixed pilot and reworked handrails. It looked good, add some of the chassis pipework and truck details and it'd give the Overland one a good run for it's money for about 1/5th the price. They're quite rare and there's one going stupid cheap at the moment but no shipping to the UK, a word with my agent in the continental US might be in order

Big Train James

Western Thunderer

Regarding current Sunset diesel locos, you would do well to clear the imagery of the early c44-9w out of your mind and start fresh. They've come a long way in the meantime.

Overland has an idler tower on one of the gear boxes, probably the middle axle on the 3 axle trucks. A photo can be found here, or a 3 axle assembly here. Up into the body it goes, then a connection via universal to the drive shaft. In my opinion, a very straightforward drive.

The tank drive is especially an issue for any dash 2, 50 series, or 60 series EMD 3 axle loco featuring the HTC-1 trucks. The transom where the inboard traction motor is mounted is a very distinctive feature, as is the mass of the traction motor itself. The tank drive shaft by default has to displace the transom and any representation of the traction motor.

I've long felt that the Overland HTC-1 trucks didn't quite look right to me, maybe proportions were off, and especially in the area of the inboard traction motor. I've come to the conclusion that perhaps the sideframe casting is correct, but the missing mass of the traction motor makes the proportions appear incorrect. One thing that is without question, the "transom" is woefully inaccurate. It might have been better to simply not even bother.

Photos are from an ebay listing, downloaded eons ago. I've no idea on attribution at this point.

And the prototype, a Don Strack photo from his wonderful Utahrails website.

No tank drives for me!!!

Edit: Unless it's an RDC

Overland has an idler tower on one of the gear boxes, probably the middle axle on the 3 axle trucks. A photo can be found here, or a 3 axle assembly here. Up into the body it goes, then a connection via universal to the drive shaft. In my opinion, a very straightforward drive.

The tank drive is especially an issue for any dash 2, 50 series, or 60 series EMD 3 axle loco featuring the HTC-1 trucks. The transom where the inboard traction motor is mounted is a very distinctive feature, as is the mass of the traction motor itself. The tank drive shaft by default has to displace the transom and any representation of the traction motor.

I've long felt that the Overland HTC-1 trucks didn't quite look right to me, maybe proportions were off, and especially in the area of the inboard traction motor. I've come to the conclusion that perhaps the sideframe casting is correct, but the missing mass of the traction motor makes the proportions appear incorrect. One thing that is without question, the "transom" is woefully inaccurate. It might have been better to simply not even bother.

Photos are from an ebay listing, downloaded eons ago. I've no idea on attribution at this point.

And the prototype, a Don Strack photo from his wonderful Utahrails website.

No tank drives for me!!!

Edit: Unless it's an RDC

Last edited:

mickoo

Western Thunderer

No, that truck does not work for me either, there's no mass inside the frames where the casting heads toward centre bolster, that 'nod' toward a chassis centre section is just wrong and the transom is quite frankly, missing.

I've done a walk around of several SD40-2 on vacation over the years, fairly sure they are HTC trucks, really not up to speed on the finer details of EMD trucks.

Florida 2015

Close up of transom.

I do need to get on and develop my GEVO truck and the HTC-R used under SD70's, M and ACe.

Again the transom is a very large visual part of the truck, as is the traction motor....which is an ideal candidate for 3D printing, I'd probably sacrifice the rear axle drive if push came to shove to get a dummy traction motor in there.

Thanks for the links to OMI drive trains, certainly moves a few projects forward, I'd have to check the GEVO for wheel spacing and dia and see if those will suffice (addendum, 5" shorter wheel base on GEVO), not overly upset if the dia is slightly out, wheel spacing might be a bit more awkward to adjust.

Mind that tower and one of the end units on each truck would suffice too....given comments on sacrificing one drive axle for visuals.

I can see me walking away with some of them to help develop my own trucks and drive around a bespoke carrying etch.

I've done a walk around of several SD40-2 on vacation over the years, fairly sure they are HTC trucks, really not up to speed on the finer details of EMD trucks.

Florida 2015

Close up of transom.

I do need to get on and develop my GEVO truck and the HTC-R used under SD70's, M and ACe.

Again the transom is a very large visual part of the truck, as is the traction motor....which is an ideal candidate for 3D printing, I'd probably sacrifice the rear axle drive if push came to shove to get a dummy traction motor in there.

Thanks for the links to OMI drive trains, certainly moves a few projects forward, I'd have to check the GEVO for wheel spacing and dia and see if those will suffice (addendum, 5" shorter wheel base on GEVO), not overly upset if the dia is slightly out, wheel spacing might be a bit more awkward to adjust.

Mind that tower and one of the end units on each truck would suffice too....given comments on sacrificing one drive axle for visuals.

I can see me walking away with some of them to help develop my own trucks and drive around a bespoke carrying etch.

Last edited:

Big Train James

Western Thunderer

Sometimes they make it really obvious.  Copyright as noted. Note that these are Dofasco cast trucks for Canadian built locos, in this case CP 6042. I don't usually see the HTC mark on domestically produced castings. That doesn't mean it never happened, I just don't feel like it's typical.

Copyright as noted. Note that these are Dofasco cast trucks for Canadian built locos, in this case CP 6042. I don't usually see the HTC mark on domestically produced castings. That doesn't mean it never happened, I just don't feel like it's typical.

Otherwise, the obvious spotting features are the extended transom on the inboard end, and the snubber on the middle axle. The significance of the HTC truck was a move to having all traction motors facing the same direction, so none had a tendency to lift, and therefor lose adhesion, due to torque when power was applied. Or something like that.

More good info from the Utahrails site, here is a summary of EMD trucks, although ironically it does not include the HTC's. There is however a separate link to a engineering study done on the HTC truck.

No need to sacrifice the inner drive axle for the traction motor, just scab it onto the gearbox housing. The drive part of the gearbox, with the guts in it, is hidden behind the wheel. The traction motor part can just be filled with air, even as part of the same housing. That's how I would do it, if designing a gearbox from scratch.

On the OMI drive components, I presume you noted that the 3 axle assembly is claimed to be for an sd70ace? Just sayin'. Regarding axle spacing, I wouldn't let that hold you back. These types of drives are usually assembled from standalone gearboxes, the drive shafts will have mating flats that are enclosed in a tube. This acts to lock the drive shafts together, and also to telescope if necessary given that the journals on these models are normally sprung. If you want something similar but different, you can always talk to Jay at Right-O-Way. His gearboxes are of the same general design as the OMI. The difference is in the power transmission, Jay uses a belt to drop power down to the gearbox, while the OMI uses a transfer tower. Also, you could have any diameter wheel on the axle, none of that is set in stone. I'll let you sort all that out.

Just sayin'. Regarding axle spacing, I wouldn't let that hold you back. These types of drives are usually assembled from standalone gearboxes, the drive shafts will have mating flats that are enclosed in a tube. This acts to lock the drive shafts together, and also to telescope if necessary given that the journals on these models are normally sprung. If you want something similar but different, you can always talk to Jay at Right-O-Way. His gearboxes are of the same general design as the OMI. The difference is in the power transmission, Jay uses a belt to drop power down to the gearbox, while the OMI uses a transfer tower. Also, you could have any diameter wheel on the axle, none of that is set in stone. I'll let you sort all that out.

Copyright as noted. Note that these are Dofasco cast trucks for Canadian built locos, in this case CP 6042. I don't usually see the HTC mark on domestically produced castings. That doesn't mean it never happened, I just don't feel like it's typical.

Copyright as noted. Note that these are Dofasco cast trucks for Canadian built locos, in this case CP 6042. I don't usually see the HTC mark on domestically produced castings. That doesn't mean it never happened, I just don't feel like it's typical.Otherwise, the obvious spotting features are the extended transom on the inboard end, and the snubber on the middle axle. The significance of the HTC truck was a move to having all traction motors facing the same direction, so none had a tendency to lift, and therefor lose adhesion, due to torque when power was applied. Or something like that.

More good info from the Utahrails site, here is a summary of EMD trucks, although ironically it does not include the HTC's. There is however a separate link to a engineering study done on the HTC truck.

No need to sacrifice the inner drive axle for the traction motor, just scab it onto the gearbox housing. The drive part of the gearbox, with the guts in it, is hidden behind the wheel. The traction motor part can just be filled with air, even as part of the same housing. That's how I would do it, if designing a gearbox from scratch.

On the OMI drive components, I presume you noted that the 3 axle assembly is claimed to be for an sd70ace?

Just sayin'. Regarding axle spacing, I wouldn't let that hold you back. These types of drives are usually assembled from standalone gearboxes, the drive shafts will have mating flats that are enclosed in a tube. This acts to lock the drive shafts together, and also to telescope if necessary given that the journals on these models are normally sprung. If you want something similar but different, you can always talk to Jay at Right-O-Way. His gearboxes are of the same general design as the OMI. The difference is in the power transmission, Jay uses a belt to drop power down to the gearbox, while the OMI uses a transfer tower. Also, you could have any diameter wheel on the axle, none of that is set in stone. I'll let you sort all that out.

Just sayin'. Regarding axle spacing, I wouldn't let that hold you back. These types of drives are usually assembled from standalone gearboxes, the drive shafts will have mating flats that are enclosed in a tube. This acts to lock the drive shafts together, and also to telescope if necessary given that the journals on these models are normally sprung. If you want something similar but different, you can always talk to Jay at Right-O-Way. His gearboxes are of the same general design as the OMI. The difference is in the power transmission, Jay uses a belt to drop power down to the gearbox, while the OMI uses a transfer tower. Also, you could have any diameter wheel on the axle, none of that is set in stone. I'll let you sort all that out.

mickoo

Western Thunderer

Jim, yes I'd noted the six axle pack was for a SD70ACe  it should also do the M as well.

it should also do the M as well.

Wheel spacing is slightly different between the HTCR and GEVO truck, the GEVO is shorter by 5" and you're right, it'd just require a tweak in the drive shafts to shorten.

Wheel diameter isn't a problem, the GEVO runs from 43" to 38", new to witness mark, a lot of folk forget real engine wheel diameter varies quite a lot through out the tyre cycle. Thus 42" is a the best value to aim for as is suits both ACe/M and ES44/ET44.

I had a quick look at RoW but couldn't see anything obvious in the way of gearboxes, I'd like to see if it's any easier to fit internal axle bearings, stub axle bearings make it awkward to design the weight carrying frame and retain detail on the printed side frames.

I do have a whole load of spare OMI gear boxes, the mazak material is shot, I did some early 3D printed replacements and for a test run, they were ok. One thing I did note is that even the useable gearboxes I have there was a terrific loading on them, they were not free running at all.

I'm not sure what the 'coasting' ability is of the newer OMI ones you linked to above, I'm going to guess a different cut of gear that allows the wheel to back drive the shaft.

it should also do the M as well.

it should also do the M as well.Wheel spacing is slightly different between the HTCR and GEVO truck, the GEVO is shorter by 5" and you're right, it'd just require a tweak in the drive shafts to shorten.

Wheel diameter isn't a problem, the GEVO runs from 43" to 38", new to witness mark, a lot of folk forget real engine wheel diameter varies quite a lot through out the tyre cycle. Thus 42" is a the best value to aim for as is suits both ACe/M and ES44/ET44.

I had a quick look at RoW but couldn't see anything obvious in the way of gearboxes, I'd like to see if it's any easier to fit internal axle bearings, stub axle bearings make it awkward to design the weight carrying frame and retain detail on the printed side frames.

I do have a whole load of spare OMI gear boxes, the mazak material is shot, I did some early 3D printed replacements and for a test run, they were ok. One thing I did note is that even the useable gearboxes I have there was a terrific loading on them, they were not free running at all.

I'm not sure what the 'coasting' ability is of the newer OMI ones you linked to above, I'm going to guess a different cut of gear that allows the wheel to back drive the shaft.

Yorkshire Dave

Western Thunderer

No tank drives for me!!!

Edit: Unless it's an RDC

Which will require two motors to drive the trucks independently as the prototype.

I don't think there is enough 'clutter' underneath to disguise the length of the propshaft if a centrally mounted motor was used.

PhilH

Western Thunderer

"no doubt Phil will educate me shortly with his uncanny knowledge of US imported brass models"

Mick

Please, spare my blushes ! Over the last 40 years I've just bought a few US brass, mainly UP, logging and D&RGW/RGS (probably too many of the latter) so I'm certainly no expert in the subject. I'm not really "in" to US diesels, so I've taken little interest in what's available in brass. I'm fairly familiar with F units, E units and GPs but I must confess that names like ACe and GEVO mean absolutely nothing to me.

If you haven't got this it may not add to your knowledge of the UP locos, but it does include details of all the other 12 coupled designs used elsewhere in the world.

The second item is a couple of articles from Continental Modeller in 1990, the first dealing with the prototype, the second with the models - mainly a comparison of the various models in HO scale. The only mention of O scale models is this rather intriguing paragraph:-

"One must acknowledge the existence of a very fine brass O scale model made by Katsumi (KTM) of Japan for Westside Models in the late 1970s. As might be imagined, at nearly 30" long this is a most impressive item in any collection and the detailing and operation are unsurpassed. But I only know of a handful of such models being imported into the UK"

The length seems a bit out, I reckon about 25" for O scale, but if it is correct it adds another possible importer/builder of the 4-12-2s.

Philip

Mick

Please, spare my blushes ! Over the last 40 years I've just bought a few US brass, mainly UP, logging and D&RGW/RGS (probably too many of the latter) so I'm certainly no expert in the subject. I'm not really "in" to US diesels, so I've taken little interest in what's available in brass. I'm fairly familiar with F units, E units and GPs but I must confess that names like ACe and GEVO mean absolutely nothing to me.

Returning to the "9s", while looking for something else I came across a couple of items I didn't realise I had at the bottom of a drawer, the first is this:

If you haven't got this it may not add to your knowledge of the UP locos, but it does include details of all the other 12 coupled designs used elsewhere in the world.

The second item is a couple of articles from Continental Modeller in 1990, the first dealing with the prototype, the second with the models - mainly a comparison of the various models in HO scale. The only mention of O scale models is this rather intriguing paragraph:-

"One must acknowledge the existence of a very fine brass O scale model made by Katsumi (KTM) of Japan for Westside Models in the late 1970s. As might be imagined, at nearly 30" long this is a most impressive item in any collection and the detailing and operation are unsurpassed. But I only know of a handful of such models being imported into the UK"

The length seems a bit out, I reckon about 25" for O scale, but if it is correct it adds another possible importer/builder of the 4-12-2s.

Philip

Last edited:

Big Train James

Western Thunderer

Mick, ROW has a tab for drive components, but no pictures of the gearboxes loaded at this time. A better option for photos might be Jay's Photobucket page. Just be aware that there is a lot of other stuff there as well, so you might have to surf around a bit for particular content. Also, I think I have some photos around here, I'll see if I can dig something up.

Regarding coasting drives, I have no idea whether the ROW or OMI drives allow for such a thing. I know that for ROW, the preferred arrangement is a gear motor with power transferred to the 1:1 ratio gearboxes via pulley and timing belt. If OMI doesn't use gear motors, then I presume the reduction occurs in the transfer tower. My impression is that coasting or back driving was eliminated by the use of a worm combined with worm gears. I don't know if there is something about either the ROW or OMI drives that inhibits coasting. You might check with your new sd75.

As far as internal bearing and rolling quality, I know that both the drive shaft and axle in an ROW gearbox are supported with roller bearings either side of a helical gears, with the bearings seated into pockets. I believe the shafts and axles are drill rod, length as required to suit your needs. Suspension at the journal is usually accomplished with shouldered axles bearing in bronze journals, with the sideframe keeping the individual boxes organized. The equally feasible alternative is to utilize flush axles, no suspension at the journal, gearboxes mounted to an internal frame, with a cosmetic sideframe casting or print hung of the internal frame. Either method makes no difference to the gearboxes themselves.

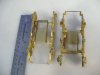

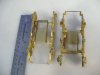

Gearbox casting

Gearbox assembly

Axles and driveshafts

Dave, the comment about the RDC was mostly rhetorical, as in I'll cross that bridge if I ever come to it, but that I could support using a jack shaft on a model if the real thing had one. You are correct about how to disguise it all, I suppose a traction type drive would work. I'm curious how Rapido manages it all on their HO model, I've never looked at one really closely, but I thought one of the marketing points was the fact that the motor was hidden under the floor.

I do now wonder, how are all of the DMU's in the UK powered, both prototypes and in model form. I presume they are somehow similar to the RDC's over here?

Jordan, I'm curious which gp38 you're going to model. If say one of the ex-MILW bandits like your gp40, like this one, will you do the short fuel tank? And would a tank drive present a problem in that case? I recognize that in many cases the drive shaft would not be visible, or barely so. But for most of the locos that I am interested in building, there are often unique circumstances where a tank drive would be incompatible with my goals.

Regarding coasting drives, I have no idea whether the ROW or OMI drives allow for such a thing. I know that for ROW, the preferred arrangement is a gear motor with power transferred to the 1:1 ratio gearboxes via pulley and timing belt. If OMI doesn't use gear motors, then I presume the reduction occurs in the transfer tower. My impression is that coasting or back driving was eliminated by the use of a worm combined with worm gears. I don't know if there is something about either the ROW or OMI drives that inhibits coasting. You might check with your new sd75.

As far as internal bearing and rolling quality, I know that both the drive shaft and axle in an ROW gearbox are supported with roller bearings either side of a helical gears, with the bearings seated into pockets. I believe the shafts and axles are drill rod, length as required to suit your needs. Suspension at the journal is usually accomplished with shouldered axles bearing in bronze journals, with the sideframe keeping the individual boxes organized. The equally feasible alternative is to utilize flush axles, no suspension at the journal, gearboxes mounted to an internal frame, with a cosmetic sideframe casting or print hung of the internal frame. Either method makes no difference to the gearboxes themselves.

Gearbox casting

Gearbox assembly

Axles and driveshafts

Dave, the comment about the RDC was mostly rhetorical, as in I'll cross that bridge if I ever come to it, but that I could support using a jack shaft on a model if the real thing had one. You are correct about how to disguise it all, I suppose a traction type drive would work. I'm curious how Rapido manages it all on their HO model, I've never looked at one really closely, but I thought one of the marketing points was the fact that the motor was hidden under the floor.

I do now wonder, how are all of the DMU's in the UK powered, both prototypes and in model form. I presume they are somehow similar to the RDC's over here?

Jordan, I'm curious which gp38 you're going to model. If say one of the ex-MILW bandits like your gp40, like this one, will you do the short fuel tank? And would a tank drive present a problem in that case? I recognize that in many cases the drive shaft would not be visible, or barely so. But for most of the locos that I am interested in building, there are often unique circumstances where a tank drive would be incompatible with my goals.

AJC

Western Thunderer

I do now wonder, how are all of the DMU's in the UK powered, both prototypes and in model form. I presume they are somehow similar to the RDC's over here?

Over the years they've tried almost any permutation you can imagine with hydraulic and mechanical transmissions (mostly with cardan shaft drives, I think) and electric transmissions in a range of different styles: the SR DEMUs from the '50s used axle-hung traction motors on what were basically EMU bogies. In model form you're either looking at a self-contained motor bogie or a central motor and cardan shafts (generally at or above floor level) driving either both bogies or just one. At least that's how it is in 4mm, I guess that 0 Gauge RTR is similar, though probably a bit more discreet.

Adam