The NER ES1 instructions include (to me) a scant paragraph relating to the pantograph - in short there are four options...

1. Build up etches as a dummy pantograph in raised position

2. Build up etches as a dummy pantograph in lowered position

3. Use a non-prototypical HO Sommerfeldt operating version

4. Make up etches as an operational model

And no prizes for the option muggins went for

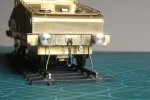

Hey presto! - an operating version.....

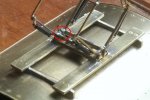

Quite simply the instructions went out of the window and I turned to previous experience based on the 7mm Harton Colliery Siemens Elok (below).

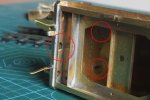

The NER ES1 pantograph (below) is not sprung in the conventional style (above) as the base is too short to include a hidden linkage to prevent the who ensemble rocking when in the raised position. It took alot of work as I cut off the dummy springs from the etch, made up upper arm end hooks from scrap etch and used four springs I had in stock.

This is a cruel crop from a photo on t'nterweb

And to prove it does work...

For a sense of scale here it is in between an O scale DB and a HO SBB pantograph.

Having seen my photos, with hindsight I'm tempted to alter the upper arm spring hooks in order to extend them but as it currently works it may be best left alone. Just need to work on a locking mechansim for the lowered position. On the prototype the pantograph was raised and lowered by an insulated hand operated rod through the cab roof.