Steve Cook

Flying Squad

Thanks Neil - using a Dremel & diamond cutting disk hadn't even occurred to me, I shall try that on the next build

I hadn't considered one for corner cuts, thats an interesting proposition....

I hadn't considered one for corner cuts, thats an interesting proposition....

Thanks TimSteve - typical clean, precise and quality build going on there, matey, very pleasing to see!

Its nice to be building again, and remembering to slow down!

Its nice to be building again, and remembering to slow down!Thanks Michael.A question about the window seals Steve. How are they removed from the platen and stay so flat and even?

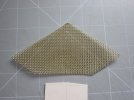

The mesh looks great.

Michael

I also need to sort a driver out so I can determine cab / seat layout - I had not thought about that until this weekend which is a bit of a bind, my usual place of purchase (Model Earth Products) don't have seated drivers unless you want the more comical sculpts so I need to consider alternatives.

Steve