Brian, don't be put off. I've seen this kit - even this particular loco - built up into splendid models. What you're seeing is my hamfistedness combining with a general malaise lurking around the place.

That said, I've definitely fallen out of love with this kit - for the time being.

I started the day soldering up some cab fittings. The fireman's perch, the reverser cabinet and a natty little etched variant on the cast flip-up seats that come in JLTRT GWR kits. I got the various parts to fit relatively neatly within the confines of the cab, so things were looking up.

Then I tried the backhead casting. Hmm. The reverser cabinet takes up some of the space, and the backhead wouldn't fit where it ought. Looking back, a pattern was beginning to develop.

After generating quite a bit of whitemetal dust, I had created a mild recess for the reverser to slot into on the side of the backhead. It's NOTHING like the real thing, but… it won't show. Rather like the photo, in fact! Anyway, happy with that butchery, and having topped up my lead content, I played about a bit with cleaning up some dodgy soldering around the frames. This is where my use of low melt solder to "temporarily" fix the axleboxes and springs came back to bite me. One axle box came adrift.

Out with the jig again, and some deft soldering later and I was more or less back at square one.

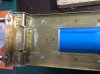

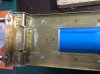

Having fixed the cab to the running plate, it sort of made sense to turn attention to sorting out the attachment of the boiler casting. There's a whitemetal saddle casting, through which one or more 10BA countersunk bolts can pass, and into the general mix an 8BA bolt is used to also hold the cylinders on. Dimples on the bottom of the smokebox indicated where to drill and tap for the bolts. At the other end, three holes in the cab front plate show where more holes can be drilled and tapped into the firebox. You can sort of see why I opted to allow the smoke deflectors to be removable, as I suspect the boiler won't come adrift so easily down the line.

So, I marked, drilled and tapped three holes into the firebox. Somehow, and don't ask me how, the holes went awry, and the whole boiler was on the squiff. I wondered why the smokebox saddle didn't want to sit in the right place, being sort of pulled off to one side. Do you see the pattern yet?

I'll have to make new holes, as I can't reuse the old ones. Bah!

What about that saddle, then?

There are two holes through the running plate. The larger one is for the cylinder assembly fixing bolt, the smaller for fixing the running plate to the smokebox. Only nine of them line up. Having fitted the saddle to the smokebox with one screw, it seems to align well enough - sort of - with the moulded detail, but seems to be set back on the running plate.

I'll need to consult the drawings to check where it should be. Even allowing for it being invisible behind the deflectors, there's a slightly yawning gap at the front with half-etch numbers and stuff on it. No obvious signs of anything to cover it later, either.

So, at this point, I decided to give the gremlins the rest of the day off. It's all back in its box, and it may be a while before it reappears again.

I might request a replacement boiler from JLTRT. It might be better to start again rather than keep peppering the current one with holes!