You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm On Heather's Workbench - Aintree Iron: an Austerity adventure

Steph Dale

Western Thunderer

Mick,

That's interesting, there appear to be numbers (tank level capacities? ) next to the gauge in that shot. That's a refinement the Southern didn't have!

Steph

That's interesting, there appear to be numbers (tank level capacities? ) next to the gauge in that shot. That's a refinement the Southern didn't have!

Steph

oldravendale

Western Thunderer

Hi Mick.

You won't regret it! There will be very little you don't know about the WD 2-8-0s by the time you've been through it.

Brian

micknich2003

Western Thunderer

Heather Kay

Western Thunderer

Thanks to Mick for the sight of the various drawings. They've already proved their worth, as I shall explain. Also, thanks to Brian for some offline information. It's all very helpful. It's quite amazing how much research material you need, even though you think you have a fair amount on the shelf!

I've already noted how some things are in the kit - and others are not - but not mentioned in the instructions. This can be frustrating at best. It's obvious the kit has been updated, and the paperwork hasn't kept pace. Onwards and sideways!

I spent a while this morning refining the bunker details. Rather happily, my guesstimate for the backplate brackets being 1ft 6in from the centreline proved correct according to the drawings. I thinned the angle down a bit, as it did look a bit clumsy. The water gauge will be fabricated at a slightly later date. I checked the photos of the engine I'm trying to build, and it does have the gauge. I'd never have spotted it without those Flickr photos from the KWVR.

I thinned the angle down a bit, as it did look a bit clumsy. The water gauge will be fabricated at a slightly later date. I checked the photos of the engine I'm trying to build, and it does have the gauge. I'd never have spotted it without those Flickr photos from the KWVR.

After that, I turned attention to the tender underparts. A spot of riveting, some laminations, and some folding later, I have the main outer frames (still needing their overlays) and the floor under way.

With the tender front posed in place, it's all beginning to look the part. After working on the MMP Mk1 kit, I had become accustomed to in-built tolerances for the etching cusp on edges. My experience of JLTRT etches is one does need to clean up the edges for a neat fit. This can be time consuming, but it is well worth the effort.

The WD tender is an imposing fabrication in real life, and the various bits of brass seem to follow the prototype quite well. Odd, then, things like the brake standard extension under the footplate is missed out. Easily resolved by a short length of brass tube, though.

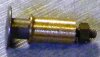

The real thing had self-contained buffers, and to be fair the following problem isn't because JLTRT has got it wrong.

Trial fitting the rear buffer beam shows the tender frames run slap down the middle of the holes where the buffer castings go, as confirmed by the GA. Some creative thinking may be needed to overcome this. An immediate thought is to fit the castings and file them flush to the back of the beam, then engineer a wire springing system to fit within the frames. I certainly can't use the standard spring-and-nut system, nor can I cut holes in the frames.

I haven't really set any targets with this build, but it might be nice to get this tender on its wheels by the end of the week. I'll see how it goes.

I've already noted how some things are in the kit - and others are not - but not mentioned in the instructions. This can be frustrating at best. It's obvious the kit has been updated, and the paperwork hasn't kept pace. Onwards and sideways!

I spent a while this morning refining the bunker details. Rather happily, my guesstimate for the backplate brackets being 1ft 6in from the centreline proved correct according to the drawings.

I thinned the angle down a bit, as it did look a bit clumsy. The water gauge will be fabricated at a slightly later date. I checked the photos of the engine I'm trying to build, and it does have the gauge. I'd never have spotted it without those Flickr photos from the KWVR.

I thinned the angle down a bit, as it did look a bit clumsy. The water gauge will be fabricated at a slightly later date. I checked the photos of the engine I'm trying to build, and it does have the gauge. I'd never have spotted it without those Flickr photos from the KWVR.After that, I turned attention to the tender underparts. A spot of riveting, some laminations, and some folding later, I have the main outer frames (still needing their overlays) and the floor under way.

With the tender front posed in place, it's all beginning to look the part. After working on the MMP Mk1 kit, I had become accustomed to in-built tolerances for the etching cusp on edges. My experience of JLTRT etches is one does need to clean up the edges for a neat fit. This can be time consuming, but it is well worth the effort.

The WD tender is an imposing fabrication in real life, and the various bits of brass seem to follow the prototype quite well. Odd, then, things like the brake standard extension under the footplate is missed out. Easily resolved by a short length of brass tube, though.

The real thing had self-contained buffers, and to be fair the following problem isn't because JLTRT has got it wrong.

Trial fitting the rear buffer beam shows the tender frames run slap down the middle of the holes where the buffer castings go, as confirmed by the GA. Some creative thinking may be needed to overcome this. An immediate thought is to fit the castings and file them flush to the back of the beam, then engineer a wire springing system to fit within the frames. I certainly can't use the standard spring-and-nut system, nor can I cut holes in the frames.

I haven't really set any targets with this build, but it might be nice to get this tender on its wheels by the end of the week. I'll see how it goes.

Last edited:

oldravendale

Western Thunderer

Trial fitting the rear buffer beam shows the tender frames run slap down the middle of the holes where the buffer castings go, as confirmed by the GA. Some creative thinking may be needed to overcome this. An immediate thought is to fit the castings and file them flush to the back of the beam, then engineer a wire springing system to fit within the frames. I certainly can't use the standard spring-and-nut system, nor can I cut holes in the frames.

I haven't really set any targets with this build, but it might be nice to get this tender on its wheels by the end of the week. I'll see how it goes.

Hi Heather.

There have been a couple of suggestions on WT about how to modify buffers to self contained such that they fit and work. I made some for a Super D. If you can't find the relevant entries let me know and I can at least outline the process I used. There was also an article in the GOG Gazette.

Brian

Heather Kay

Western Thunderer

Thanks, Brian. I'll do a forum search later.

Heather Kay

Western Thunderer

By the way, MOK do some nice LMS style self contained buffers, but they are not quite right for the WD. It might be possible to modify them..

Interesting. Having had a quick squint at his web site, it's not apparent whether he supplies such things outside of kits. I guess I could call and find out.

Heather Kay

Western Thunderer

I just found this PDF on Dave Sharp's web site.

http://www.modernoutline.co.uk/ivatt_16_inch_buffer_instructions.pdf

The design is exactly the same as Brian's technique. I shall contact Dave and see if the buffers from the Ivatt kit can be supplied separately.

http://www.modernoutline.co.uk/ivatt_16_inch_buffer_instructions.pdf

The design is exactly the same as Brian's technique. I shall contact Dave and see if the buffers from the Ivatt kit can be supplied separately.

Heather Kay

Western Thunderer

While I ponder self-contained buffers, I am also pondering substituting sprung buffers for the front of the tender.

There are some nice little cast bufferlets in the kit, and I'm sure they would be fine in service. However, from my 4mm days, I have some MJT style sprung coach buffers which could be pressed into service.

Is it worth it? A step too far, perhaps?

There are some nice little cast bufferlets in the kit, and I'm sure they would be fine in service. However, from my 4mm days, I have some MJT style sprung coach buffers which could be pressed into service.

Is it worth it? A step too far, perhaps?

Last edited:

oldravendale

Western Thunderer

I just found this PDF on Dave Sharp's web site.

http://www.modernoutline.co.uk/ivatt_16_inch_buffer_instructions.pdf

The design is exactly the same as Brian's technique. I shall contact Dave and see if the buffers from the Ivatt kit can be supplied separately.

Honest, Heather, I didn't know about these when I discussed my technique previously, although I made due homage to the article in the GOG Journal whichwas the direct inspiration. In fact, I'll certainly consider the MOK ones myself should a further need for self contained buffers arise, and it most certainly will! The question then will be whether it's quicker to make my own from the (hopefully) accurate ones in the kit or spend time modifying the MOK ones.

Brian

Steph Dale

Western Thunderer

Mick,

Yeah, the WD gauge seems the same principal just a slightly trickier implementation than the Southern version...!

Steph

Yeah, the WD gauge seems the same principal just a slightly trickier implementation than the Southern version...!

Steph

Steph Dale

Western Thunderer

Trickier?, surely simpler, if I understand the Southern way correctly, it's a tube within a tube, under war time conditions that could become damaged or full of grit / detritus and fail, I work in a 'mildly' hostile environment to equipment and the Southern way would soon have issues with corrosion and the inner tube sticking.

On first observations the only Achilles heel to the WD method is the valve at the base, the hollow handle is simple as simple does, in a pinch you could pull the handle out and just let the water spout upward, the crest of said fountain being the water level, then all you'd need do is wedge a wooden plug in the tap to stop the flow.

90775 is based at the NNR which is just up the road to me, if I'm that way I'll pop by and ask them first hand how it works.....with photos of course LOL.

But the Southern version doesn't require the manufacture, sealing and fitting of the valve nor the sourcing of the washer to make it seal (and you'd be surprised how tricky they were to find in field conditions, or even in the austerity years - there was a shortage of leather at the time...). I'd go with the simpler solution every time...

Steph

Heather Kay

Western Thunderer

Just bringing things back to buffers, I emailed Dave Sharp earlier today. Here's his reply:

I guess I'll make an order then.

Thanks for the enquiry, must remember to get these added to the websit products area together with the BR Speedo.

Answer is yes £10.95 a set.

I guess I'll make an order then.

OzzyO

Western Thunderer

Looking at it now, all it is, is a hollow pipe with a number of holes in it. For it to work you just turn it through 90 degs. it then opens the tap at the bottom and the water will then fill the tube until it reaches the max. hight. It will also clear all of the lower holes due to them being open at the same time. The water pressure in the tank should help keep the gauge working!!!

OzzyO

OzzyO

Heather Kay

Western Thunderer

Heather, which loco are you modelling, I may have some images that might help.

It's 90643. I have two pretty clear shots from front three-quarters of both sides. I'd love to find out which tender it has so I can get appropriate plates, but I think it's going to have to be a lottery pick. The images are some time in the mid-1960s, so the loco's original tender may well have been swapped out a few times by then.