The postman came today and delivered all the usual c***, a bill, and some very well packed nickel silver strips suitable for frames and the like. I can no longer prevaricate this job into indecision, so a start was made.

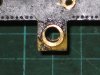

The chassis is held into the body by this screw that also retained the bogie,

and a tab soldered to the underside of the cab floor that pokes through the rear stretcher of the frames.

The frames drops at the front and pulls forward to release it.

There is nothing particularly unusual about the bogie, it might be a kit etching but could equally be not so, it will need replacing. The coupling rods are reusable if in need of a clean up, but the crankpins are currently 6BA csk brass screws into the rear of the drivers and they are considerably undersized for the holes they fit into.

Removing the wheels, axles and motor left the bare frames, pretty they are not.

They look distinctly odd, the position of the bearings for the driving wheels makes no sense until I realised that the frame top doesn't meet the underside of the footplate. They look as though they were etched but I can find no identifying marks on the frames or the inside of the body to confirm this, nor whether it's a kit or not, I'm tending towards not. Frankly it's not worth spending any effort on as I suspected so a new one is the order of the day, but I think some drawings and possibly a plastikard mock up before metal is cut, some thinking to do here.

Regards

Martin

I barely run half a turn if that before backing off to remove the chip. Although I'd agree with using the pin vice for better feel.

I barely run half a turn if that before backing off to remove the chip. Although I'd agree with using the pin vice for better feel.