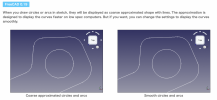

One of Tinkercad’s annoyances is that curves and circles are represented as multi-faceted stepped surfaces, not true curves. Files exported as STLs for printing retain this unhelpful geometric design.

However I’ve just stumbled on a way to avoid this entirely and get pure curves that I haven’t seen documented elsewhere;

You’ll need a copy of Fusion 360 installed (available for free use, subject to licence).

When you’ve finished designing in Tinkercad, instead of exporting in stl or obj formats, use the ‘send to’ command. The file is then sent to Fusion 360 where it arrives as a fully editable design. You then just save the file, which allows you to export it in your chosen format (stl, obj etc). (You need to save it in Fusion for exporting to be an option.)

You can get the benefit of this without any significant knowledge of Fusion, other than ‘save’ and ‘export’.

The other great benefit of this workflow is that the design in Fusion remains properly editable for those that have some basic knowledge of Fusion. This allows you to utilise some of functions in Fusion that are easy to use, eg chamfer, fillet, cove, threaded holes etc that are hideously complex(impossible?) in Tinkercad, but simple to use in Fusion.

The one annoyance is that this workflow won’t work with structures not built from Tinkercad's primitives (basic shapes). So if you’ve used shape generators or imported pre made designs and edited them you can’t send them out to Fusion.

However I’ve just stumbled on a way to avoid this entirely and get pure curves that I haven’t seen documented elsewhere;

You’ll need a copy of Fusion 360 installed (available for free use, subject to licence).

When you’ve finished designing in Tinkercad, instead of exporting in stl or obj formats, use the ‘send to’ command. The file is then sent to Fusion 360 where it arrives as a fully editable design. You then just save the file, which allows you to export it in your chosen format (stl, obj etc). (You need to save it in Fusion for exporting to be an option.)

You can get the benefit of this without any significant knowledge of Fusion, other than ‘save’ and ‘export’.

The other great benefit of this workflow is that the design in Fusion remains properly editable for those that have some basic knowledge of Fusion. This allows you to utilise some of functions in Fusion that are easy to use, eg chamfer, fillet, cove, threaded holes etc that are hideously complex(impossible?) in Tinkercad, but simple to use in Fusion.

The one annoyance is that this workflow won’t work with structures not built from Tinkercad's primitives (basic shapes). So if you’ve used shape generators or imported pre made designs and edited them you can’t send them out to Fusion.

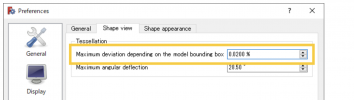

) we are using digital computers so it will it will always be a faceted stepped surface to some degree for a curve. You just need to adjust the resolution so that you can no longer distinguish the steps, the closest you can get is to convert to vector format and bezier curves, but as the screen you are using is digital it will still be a stepped surface.

) we are using digital computers so it will it will always be a faceted stepped surface to some degree for a curve. You just need to adjust the resolution so that you can no longer distinguish the steps, the closest you can get is to convert to vector format and bezier curves, but as the screen you are using is digital it will still be a stepped surface.