David Taylor

Western Thunderer

Hi all. As promised in my "hello" message here is a thread about models I'm working on.

The first model I tried to build is an 0-6-0 tank loco called an 18-class in NSW. It has 1/16" brass frames, rigid chassis in Slaters top-hat bearings, flangeless middle wheels, it even had coupling rods made from filed down rail. Straight out of the 30s, except it is only 10 years old. It never got finished. I got sick of making new chassis for it, and the bodywork isn't too hot either.

Next up was a hearse. Plastic body, wooden underframe, home etched underframe details. I never got the roof onto it because it requires a double-roof (we had a lot of them out here to keep the heat down) with ornate little pillars and filligree to hold the two roofs apart. I couldn't figure out how to make them. Then the underframe fell apart because it was put together with PVA. I still have the body somewhere in the shed.

Now an open wagon, called a D wagon. Another plastic body, the wooden underframe had all the proper timber

members and the floor had individual planks, and more home etched underframe details. Fully sprung wheels. I tried making the brake work on this one, but it didn't turn out. I came home one day to find it all bent out of shape after my wife gave it to the kids to play with.

Another D wagon, from a kit this time. I put this off for years because the instructions were badly photocopied and I couldn't figure out how it went together. I eventually asked the manufacturer for some help and he sent me enough photos of his build that I could get on with it. It's actually a ripper of a kit - everything fit just right, heaps of detail including things like the metal strapping along the top of the body, springs made from individual leaves, holes etched for scale hardware nuts, working handbrake... But I'm too cheap to buy the nuts and too lazy to make them so it can't be painted yet.

Now a Slater's K class Manning Wardle with an extra etch to make it into one which we had in NSW. The etch is from the same place as the D wagon kit above. This was the first (and only) locomotive kit I've built and I found it a real pig to work on. I didn't enjoy it at all but it cost a bundle so I forced myself to try and finish it. I had to cut the top and bottom from the chimney and turn a new middle part to match the longer chimney on our local version. The kit is done aside from the reversing lever and reach rod, sandboxes (the ones in the kit are incorrect for my prototype), drain cock operating links, and assorted plumbing around the saddle tank which I can't find details of. It runs like a dog, but I can't be bothered to try and fix it. Not my favourite model.

Now the 4-4-0 built by Dubs. I think this is one of the most elegent locos we had in NSW, until they started putting standard Belpaire boilers on them which made them quite messy and ugly like most NSW locos post 1900. I'm modelling it as delivered with a round topped firebox and sloping smokebox. This loco has Joy valve gear which I'm trying to model. The loco is on it's 3rd set of frames, 2nd body, heavily chopped and patched boiler, 2nd crank axle, cylinders, motion plate, etc. It's quite a learning experience. In despair at breaking more drills making fiddly little valve gear components I made a start on the tender which has split frames. I'm pretty happy with the way the tender is, going it being put together pretty much on the fly and without a lot of planning (as are all my models!)

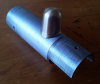

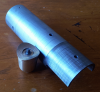

And today, while putting off trying to add the studs around the new rear cylinder covers for the 4-4-0 I decided to dig out that first effort at a loco and redo the frames. The plan is to keep the super-thick frames themselves but use hornblocks with roller bearings, split-axles, and have a go at making milled coupling rods. If all that works out I then have to make a new body to bring it up to standard I guess. Later is a photo showing a before/after shot of one cleaned up frame and one just out of the flames. As these aren't modern girly-man frames a soldering iron wasn't up to the job of dismantling them.

So there you go - many starts, no finishes, countless mistakes, accidents, and tragedy, . When I get around to S scale (probably LSWR), I'm going to choose the most plain loco I can find, not put any inside valve gear on it, get the damned thing running and painted, and call it a day. Shame I only own the book of pre-1900 locos!

Hmmm, I can't add any more photos to this post. I'll put them in the next one.

Regards,

David.

The first model I tried to build is an 0-6-0 tank loco called an 18-class in NSW. It has 1/16" brass frames, rigid chassis in Slaters top-hat bearings, flangeless middle wheels, it even had coupling rods made from filed down rail. Straight out of the 30s, except it is only 10 years old. It never got finished. I got sick of making new chassis for it, and the bodywork isn't too hot either.

Next up was a hearse. Plastic body, wooden underframe, home etched underframe details. I never got the roof onto it because it requires a double-roof (we had a lot of them out here to keep the heat down) with ornate little pillars and filligree to hold the two roofs apart. I couldn't figure out how to make them. Then the underframe fell apart because it was put together with PVA. I still have the body somewhere in the shed.

Now an open wagon, called a D wagon. Another plastic body, the wooden underframe had all the proper timber

members and the floor had individual planks, and more home etched underframe details. Fully sprung wheels. I tried making the brake work on this one, but it didn't turn out. I came home one day to find it all bent out of shape after my wife gave it to the kids to play with.

Another D wagon, from a kit this time. I put this off for years because the instructions were badly photocopied and I couldn't figure out how it went together. I eventually asked the manufacturer for some help and he sent me enough photos of his build that I could get on with it. It's actually a ripper of a kit - everything fit just right, heaps of detail including things like the metal strapping along the top of the body, springs made from individual leaves, holes etched for scale hardware nuts, working handbrake... But I'm too cheap to buy the nuts and too lazy to make them so it can't be painted yet.

Now a Slater's K class Manning Wardle with an extra etch to make it into one which we had in NSW. The etch is from the same place as the D wagon kit above. This was the first (and only) locomotive kit I've built and I found it a real pig to work on. I didn't enjoy it at all but it cost a bundle so I forced myself to try and finish it. I had to cut the top and bottom from the chimney and turn a new middle part to match the longer chimney on our local version. The kit is done aside from the reversing lever and reach rod, sandboxes (the ones in the kit are incorrect for my prototype), drain cock operating links, and assorted plumbing around the saddle tank which I can't find details of. It runs like a dog, but I can't be bothered to try and fix it. Not my favourite model.

Now the 4-4-0 built by Dubs. I think this is one of the most elegent locos we had in NSW, until they started putting standard Belpaire boilers on them which made them quite messy and ugly like most NSW locos post 1900. I'm modelling it as delivered with a round topped firebox and sloping smokebox. This loco has Joy valve gear which I'm trying to model. The loco is on it's 3rd set of frames, 2nd body, heavily chopped and patched boiler, 2nd crank axle, cylinders, motion plate, etc. It's quite a learning experience. In despair at breaking more drills making fiddly little valve gear components I made a start on the tender which has split frames. I'm pretty happy with the way the tender is, going it being put together pretty much on the fly and without a lot of planning (as are all my models!)

And today, while putting off trying to add the studs around the new rear cylinder covers for the 4-4-0 I decided to dig out that first effort at a loco and redo the frames. The plan is to keep the super-thick frames themselves but use hornblocks with roller bearings, split-axles, and have a go at making milled coupling rods. If all that works out I then have to make a new body to bring it up to standard I guess. Later is a photo showing a before/after shot of one cleaned up frame and one just out of the flames. As these aren't modern girly-man frames a soldering iron wasn't up to the job of dismantling them.

So there you go - many starts, no finishes, countless mistakes, accidents, and tragedy, . When I get around to S scale (probably LSWR), I'm going to choose the most plain loco I can find, not put any inside valve gear on it, get the damned thing running and painted, and call it a day. Shame I only own the book of pre-1900 locos!

Hmmm, I can't add any more photos to this post. I'll put them in the next one.

Regards,

David.