You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm AdamF's Scale7 Western Workbench

- Thread starter AdamF

- Start date

Steph Dale

Western Thunderer

Again, many thanks for the info guys - really appreciated

I think I will definitely go with Finney units now - they look super.

My only concern is that the slots already in the frames could be too wide (12mm across)... Fingers crossed!

Adam,

I think you'll be just about okay at 12mm.

Steph

AdamF

Western Thunderer

Another session at the workbench this weekend

Following the kind advice above I invested in some Finney early GWR hornguide units. They are very easy to put together and are of much better dimensions for the 517 chassis.

Following assembly, two were soldered to the frames for the compensated rear driving axle:

They aligned very well with the shape of the bottom of the frame (although you can see there is some excess at the top, which I aiming to keep unless the superstructure requires them to be taken flush to the top of the frame). Once the ride is sorted, I'll look at manufacturing some axle keeps.

The frames have now been soldered together (making sure that everything was square using an axle alignment jig (configured using the coupling rods laminated earlier) and engineer's square (the spacers are the S7 spacers which come with the kit)):

Unfortunately, the blue now looks a bit ugly!

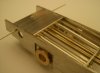

I've also managed to make a start on the compensation system, which, although very cleverly designed to fork around the motor and gearbox, I found a little bit fiddly to solder and fold up to clear the motor and gearbox assembly and the hornblocks (another reason I am glad to be modelling in S7 - the clearances are just that much more generous for my clumsy work :

:

The clearances are still quite tight:

That's all for now.

Next steps will be to set the ride height for the wheels and compensation beam and fix the mechanism in followed by starting to detail the chassis.

Time for a beer!

Following the kind advice above I invested in some Finney early GWR hornguide units. They are very easy to put together and are of much better dimensions for the 517 chassis.

Following assembly, two were soldered to the frames for the compensated rear driving axle:

They aligned very well with the shape of the bottom of the frame (although you can see there is some excess at the top, which I aiming to keep unless the superstructure requires them to be taken flush to the top of the frame). Once the ride is sorted, I'll look at manufacturing some axle keeps.

The frames have now been soldered together (making sure that everything was square using an axle alignment jig (configured using the coupling rods laminated earlier) and engineer's square (the spacers are the S7 spacers which come with the kit)):

Unfortunately, the blue now looks a bit ugly!

I've also managed to make a start on the compensation system, which, although very cleverly designed to fork around the motor and gearbox, I found a little bit fiddly to solder and fold up to clear the motor and gearbox assembly and the hornblocks (another reason I am glad to be modelling in S7 - the clearances are just that much more generous for my clumsy work

:

:

The clearances are still quite tight:

That's all for now.

Next steps will be to set the ride height for the wheels and compensation beam and fix the mechanism in followed by starting to detail the chassis.

Time for a beer!

Steph Dale

Western Thunderer

Another session at the workbench this weekend

Following the kind advice above I invested in some Finney early GWR hornguide units. They are very easy to put together and are of much better dimensions for the 517 chassis.

Following assembly, two were soldered to the frames for the compensated rear driving axle:

They aligned very well with the shape of the bottom of the frame (although you can see there is some excess at the top, which I aiming to keep unless the superstructure requires them to be taken flush to the top of the frame). Once the ride is sorted, I'll look at manufacturing some axle keeps.

The frames have now been soldered together (making sure that everything was square using an axle alignment jig (configured using the coupling rods laminated earlier) and engineer's square (the spacers are the S7 spacers which come with the kit)):

Unfortunately, the blue now looks a bit ugly!

I've also managed to make a start on the compensation system, which, although very cleverly designed to fork around the motor and gearbox, I found a little bit fiddly to solder and fold up to clear the motor and gearbox assembly and the hornblocks (another reason I am glad to be modelling in S7 - the clearances are just that much more generous for my clumsy work:

The clearances are still quite tight:

That's all for now.

Next steps will be to set the ride height for the wheels and compensation beam and fix the mechanism in followed by starting to detail the chassis.

Time for a beer!

Adam,

Neat work and a very nice recovery...!

Steph

AdamF

Western Thunderer

A welcome return to the workbench today  after a busy start to the New Year with work and no modelling over Christmas

after a busy start to the New Year with work and no modelling over Christmas

Mid-way through the week I found a very exciting package on the doormat - my reprofiled wheels

I ended up purchasing Slaters wheels and having them reprofiled to GWR tyre and hub dimensions and chemically blackened for effect and protection from flux erosion. I am really taken with how fine the reprofiled wheels look:

I could now start further work on the chassis - balancing the ride height of the compensation and fixing on the details using the wheels to judge clearances.

This morning, a dry run of the wheels and compensation unit showed that the ride height was too low at the rear by 1.5mm which would require alteration to the part of the beam pressing on the trailing wheel axle:

I spent the day making the necessary alterations, fixing in the compensation unit and starting to detail the chassis - pics to follow tomorrow when I will have better light

Adam

after a busy start to the New Year with work and no modelling over Christmas

after a busy start to the New Year with work and no modelling over Christmas

Mid-way through the week I found a very exciting package on the doormat - my reprofiled wheels

I ended up purchasing Slaters wheels and having them reprofiled to GWR tyre and hub dimensions and chemically blackened for effect and protection from flux erosion. I am really taken with how fine the reprofiled wheels look:

I could now start further work on the chassis - balancing the ride height of the compensation and fixing on the details using the wheels to judge clearances.

This morning, a dry run of the wheels and compensation unit showed that the ride height was too low at the rear by 1.5mm which would require alteration to the part of the beam pressing on the trailing wheel axle:

I spent the day making the necessary alterations, fixing in the compensation unit and starting to detail the chassis - pics to follow tomorrow when I will have better light

Adam

AdamF

Western Thunderer

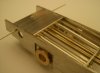

Pics of yesterday's progress (not much mind you  ), after the compensation beam had been adjusted and the chassis detail overlays and brake hanger wire (left over-long to allow easy adjustment of the brake hangers and shoes) added:

), after the compensation beam had been adjusted and the chassis detail overlays and brake hanger wire (left over-long to allow easy adjustment of the brake hangers and shoes) added:

A close up to give an idea of the overlay detail e.g. the tank mounting brackets:

Next to do will be to fit the dummy motion details, brakes and other sub-structure detail like the ashpan. I also want to do something about the area around the hornguides - the tab and slot design of the Finney units is very visible and I think I will need to fill in this area with some nickel silver section.

Other things to do will include adding leafspring detail under the rear drivers (I removed the the leafspring representation that was etched to the frames to allow easy fit of the hornguides) and the front drivers. I also need to think about whether I need to fill the gaps around the front driver axle bush - not sure whether it is prototypical? It doesn't seem to be from the photographs I am looking at.

So far the kit has gone together extremely well with the most basic of tools - a real pleasure to build I can't wait to see how it is finally going to come out! Could be a while though

I can't wait to see how it is finally going to come out! Could be a while though

), after the compensation beam had been adjusted and the chassis detail overlays and brake hanger wire (left over-long to allow easy adjustment of the brake hangers and shoes) added:

), after the compensation beam had been adjusted and the chassis detail overlays and brake hanger wire (left over-long to allow easy adjustment of the brake hangers and shoes) added:

A close up to give an idea of the overlay detail e.g. the tank mounting brackets:

Next to do will be to fit the dummy motion details, brakes and other sub-structure detail like the ashpan. I also want to do something about the area around the hornguides - the tab and slot design of the Finney units is very visible and I think I will need to fill in this area with some nickel silver section.

Other things to do will include adding leafspring detail under the rear drivers (I removed the the leafspring representation that was etched to the frames to allow easy fit of the hornguides) and the front drivers. I also need to think about whether I need to fill the gaps around the front driver axle bush - not sure whether it is prototypical? It doesn't seem to be from the photographs I am looking at.

So far the kit has gone together extremely well with the most basic of tools - a real pleasure to build

I can't wait to see how it is finally going to come out! Could be a while though

I can't wait to see how it is finally going to come out! Could be a while though

AdamF

Western Thunderer

Were the wheels reprofiled by Christopher Makepeace ?

JB.

They were indeed - fantastic service! Really quick and he even machined me a new trailing axle after thinning the trailing wheel hubs left them too loose a fit on the original axle

AdamF

Western Thunderer

A bit more work on the chassis today - fitting the slide bars, piston rods and valve rod detail:

Filing still needs to be completed in places.

Slightly annoyingly, I hadn't checked the clearances of the bottom slide bars near the frames with the axle bushes - they wouldn't clear the bushes In the end, I put it down to experience and compromised by not including that slide bar - I hope when the engine is finished that it won't be too noticeable (not very thorough, I know). I am still quite pleased with the results, although it looked a little "busy" at first! Hopefully, with some painting and the body mounted it will look ok.

In the end, I put it down to experience and compromised by not including that slide bar - I hope when the engine is finished that it won't be too noticeable (not very thorough, I know). I am still quite pleased with the results, although it looked a little "busy" at first! Hopefully, with some painting and the body mounted it will look ok.

I have to say, following putting in some dummy motion, I have complete respect for anyone who incorporates the working version in their builds

Maybe some more work tomorrow, hanging the brakes and starting to assemble the brake gear.

Adam

Filing still needs to be completed in places.

Slightly annoyingly, I hadn't checked the clearances of the bottom slide bars near the frames with the axle bushes - they wouldn't clear the bushes

In the end, I put it down to experience and compromised by not including that slide bar - I hope when the engine is finished that it won't be too noticeable (not very thorough, I know). I am still quite pleased with the results, although it looked a little "busy" at first! Hopefully, with some painting and the body mounted it will look ok.

In the end, I put it down to experience and compromised by not including that slide bar - I hope when the engine is finished that it won't be too noticeable (not very thorough, I know). I am still quite pleased with the results, although it looked a little "busy" at first! Hopefully, with some painting and the body mounted it will look ok.I have to say, following putting in some dummy motion, I have complete respect for anyone who incorporates the working version in their builds

Maybe some more work tomorrow, hanging the brakes and starting to assemble the brake gear.

Adam

AdamF

Western Thunderer

Very nice and clean work. How much clearance is required for the bottom outer slidebar? What about thinning the top of the bush or the bottom of the slidebar?

What is the purpose of the rod between the two valve rods?

Thanks Graham!

Actually, the clearance needed is about 0.7mm - I may be able to do something by way of thinning the slidebar (watch this space!)

As to the purpose of the rod between the two valve rods - this is where my complete inexperience will show

I don't know, there was a hole in the frame spacer below the valve rods, I thought it needed an additional rod and I fitted it

I don't know, there was a hole in the frame spacer below the valve rods, I thought it needed an additional rod and I fitted it  Still feeling my way on the engineering side of things

Still feeling my way on the engineering side of things

Could I throw it open to Western Thunder - should it be there and, if so, what is it for?

Dog Star

Western Thunderer

Suppose the hole/rod is for a modelling need rather than a prototypical bit of kit? Given that the kit design includes compensation, might this be the pivot for the front axle? I am not aware of Swindon fitting steam chest gauges to any engines contemporary with the 517 class.

AdamF

Western Thunderer

I must admit, I can't really think what it might be for other than some kind of steam chest pressure gauge pipe perhaps..?

JB.

Suppose the hole/rod is for a modelling need rather than a prototypical bit of kit? Given that the kit design includes compensation, might this be the pivot for the front axle? I am not aware of Swindon fitting steam chest gauges to any engines contemporary with the 517 class.

Thanks guys.

It could be for a front axle pivot (the instructions suggest it can be done) but the hole sits too high above the axle datum - perhaps this will remain a bit of a mystery!!

Adam

AdamF

Western Thunderer

Progress!

After two full on weeks and weekends at work, I have managed to spend some more time (between the rugby) at the workbench

This weekend's task was to add the brake hanger and pullrod detail.

Brake hangers come as a front and back etch which has to be laminated together - with bulldog clips and some hanger wire through the holes, this all lined up well, although broaching, soldering and filing back was time consuming.

Soldering the hangers to the hanger rods was a really fiddly task, especially having to calibrate the rear driver brakes with a floating axle! I ended up fixing things in place with blue-tak (which has become a real ally in difficult spots - I find it invaluable to hold pieces in place for soldering. My newbie tip of the day ) and being very careful with the iron (only precision soldering has shown up how much of a tremble I can have - I often have to hold the iron in both hands

) and being very careful with the iron (only precision soldering has shown up how much of a tremble I can have - I often have to hold the iron in both hands  )!

)!

If anyone has any tips on making brake assembly an easier job for future builds it would be great to hear them

In the end, I am quite pleased with the results:

Once the pullrods have been soldered in place, the whole brake assembly is surprisingly rigid and strong.

My one concern is that the distance between the pullrods and the brake hangers might be over-wide, but there is nothing I can do about that now To be fair, that distance was mostly dictated by the need to fit the brake operating levers around the pullrod ends within the frame sides. Down it goes in the experience book - I'm sure that a bit of work could have fixed that had I spotted it early enough!

To be fair, that distance was mostly dictated by the need to fit the brake operating levers around the pullrod ends within the frame sides. Down it goes in the experience book - I'm sure that a bit of work could have fixed that had I spotted it early enough!

That was enough work for this weekend - I don't want to rush it. She's starting to look more like a loco Ashpan and further chassis detail next (after double-checking motion under own power).

Ashpan and further chassis detail next (after double-checking motion under own power).

Adam

After two full on weeks and weekends at work, I have managed to spend some more time (between the rugby) at the workbench

This weekend's task was to add the brake hanger and pullrod detail.

Brake hangers come as a front and back etch which has to be laminated together - with bulldog clips and some hanger wire through the holes, this all lined up well, although broaching, soldering and filing back was time consuming.

Soldering the hangers to the hanger rods was a really fiddly task, especially having to calibrate the rear driver brakes with a floating axle! I ended up fixing things in place with blue-tak (which has become a real ally in difficult spots - I find it invaluable to hold pieces in place for soldering. My newbie tip of the day

) and being very careful with the iron (only precision soldering has shown up how much of a tremble I can have - I often have to hold the iron in both hands

) and being very careful with the iron (only precision soldering has shown up how much of a tremble I can have - I often have to hold the iron in both hands  )!

)!If anyone has any tips on making brake assembly an easier job for future builds it would be great to hear them

In the end, I am quite pleased with the results:

Once the pullrods have been soldered in place, the whole brake assembly is surprisingly rigid and strong.

My one concern is that the distance between the pullrods and the brake hangers might be over-wide, but there is nothing I can do about that now

To be fair, that distance was mostly dictated by the need to fit the brake operating levers around the pullrod ends within the frame sides. Down it goes in the experience book - I'm sure that a bit of work could have fixed that had I spotted it early enough!

To be fair, that distance was mostly dictated by the need to fit the brake operating levers around the pullrod ends within the frame sides. Down it goes in the experience book - I'm sure that a bit of work could have fixed that had I spotted it early enough!That was enough work for this weekend - I don't want to rush it. She's starting to look more like a loco

Ashpan and further chassis detail next (after double-checking motion under own power).

Ashpan and further chassis detail next (after double-checking motion under own power).Adam

Scale7JB

Western Thunderer

Looking Nice Adam, but one of those pictures raises a point that one of us S7ers should have spotted a lot sooner...!

What width frame spacers are you using? Do you know what the width of the frames was on the prototype? I'm pretty sure that the wheels on the prototype would have been taking gouges out of the frames....

JB.

What width frame spacers are you using? Do you know what the width of the frames was on the prototype? I'm pretty sure that the wheels on the prototype would have been taking gouges out of the frames....

JB.

AdamF

Western Thunderer

Looking Nice Adam, but one of those pictures raises a point that one of us S7ers should have spotted a lot sooner...!

What width frame spacers are you using? Do you know what the width of the frames was on the prototype? I'm pretty sure that the wheels on the prototype would have been taking gouges out of the frames....

JB.

Thanks JB.

The frame spacers are 24.70mm giving rise to frames which are 27mm over outer faces. These were the Scale7 spacers included with the kit.

I'm not sure what the prototype frame width was, I'm going to have to look that up, but I'm getting the sense I'm not going to like the outcome

This could be interesting - I'll post back when I find out...

This could be interesting - I'll post back when I find out...A

Scale7JB

Western Thunderer

See if you can find out what the width would be, but I'm guessing you may need to widen those frames by about 2mm at least... I don't know too much about these engines, but all of the 0-4-4/0-6-2/2-4-2 engines that I have built so far have frames at full width behind the drivers to fit in the valve gear, with cranked narrower frames behind any guiding wheels to allow for the sideways movement for a pony or radial truck..

It would be interesting actually to know wether it was a radial truck (rather than a pony truck) on the 517 class, as in drawing some up in 3D for use on my N7 and F5..

If you do find out that the frames need to be wider, and you choose to go ahead and amend them, yes it's a small bugger, but the visual impact of having the frames nearer the spacers is massively better...

I just wish I had noticed it in the earlier pictures..! Sorry mate...

JB.

It would be interesting actually to know wether it was a radial truck (rather than a pony truck) on the 517 class, as in drawing some up in 3D for use on my N7 and F5..

If you do find out that the frames need to be wider, and you choose to go ahead and amend them, yes it's a small bugger, but the visual impact of having the frames nearer the spacers is massively better...

I just wish I had noticed it in the earlier pictures..! Sorry mate...

JB.

AdamF

Western Thunderer

See if you can find out what the width would be, but I'm guessing you may need to widen those frames by about 2mm at least... I don't know too much about these engines, but all of the 0-4-4/0-6-2/2-4-2 engines that I have built so far have frames at full width behind the drivers to fit in the valve gear, with cranked narrower frames behind any guiding wheels to allow for the sideways movement for a pony or radial truck..

It would be interesting actually to know wether it was a radial truck (rather than a pony truck) on the 517 class, as in drawing some up in 3D for use on my N7 and F5..

If you do find out that the frames need to be wider, and you choose to go ahead and amend them, yes it's a small bugger, but the visual impact of having the frames nearer the spacers is massively better...

JB.

Still haven't bottomed this one out yet, but getting the uneasy feeling that you may be right JB!!

If it is the case, there'll be a lot of

and a fair amount of

and a fair amount of  but my modelling time is precious and little and it would be just too many backwards steps at this stage for me to undo the work to date - the visual impact will be compromised, absolutely, but I think I'd rather put that down to experience (next time, research, research, research!!) and crack on for a finished model before the year end!

but my modelling time is precious and little and it would be just too many backwards steps at this stage for me to undo the work to date - the visual impact will be compromised, absolutely, but I think I'd rather put that down to experience (next time, research, research, research!!) and crack on for a finished model before the year end!To be fair, I wasn't expecting my first kit build to come out blemish free

and the opportunity to learn from mistakes is one of the hidden benefits - I'm still loving the hobby

and the opportunity to learn from mistakes is one of the hidden benefits - I'm still loving the hobby  There will be a chance for redemption - I have my eye on an LSWR M7 for the next build...

There will be a chance for redemption - I have my eye on an LSWR M7 for the next build...I just wish I had noticed it in the earlier pictures..! Sorry mate...

JB.

No worries - entirely my mistake

If I get to an answer on the dimensions and frame styling, I'll let you know.

A