Nick Dunhill

Western Thunderer

I have to confess to being a bit out of my comfort zone with this project, so I was a bit unsure about whether to upload this. I have been commissioned to build a pair of Armstrong Goods convertible locos from Scorpio (loco) and Broad Gauge Society (tender) kits. There seems to be a paucity of information about the broad gauge versions (photography in it's infancy?), but fairly lenghty chats with Pat Ennis at Scorpio and Peter Boyce at the BGS put my mind at rest.

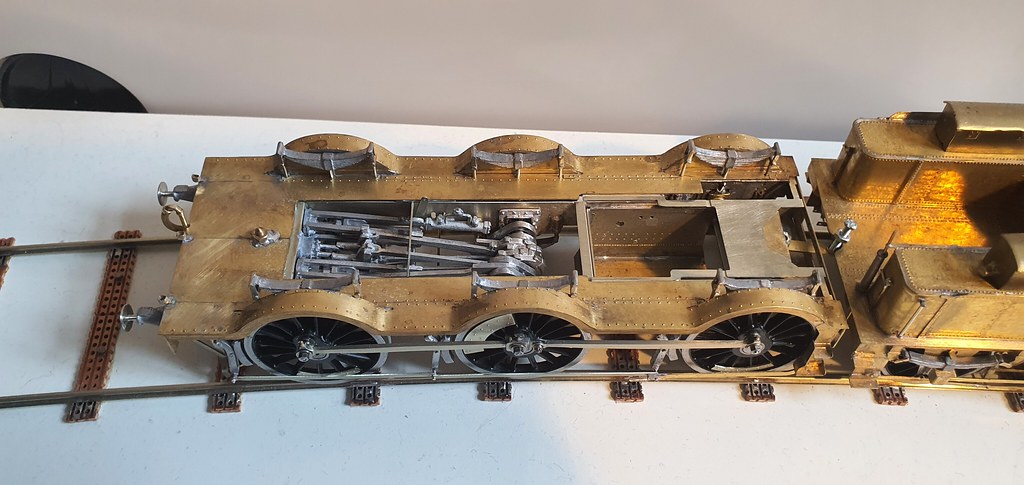

The tender kits from the Broad Gauge society are ok. They are a 4mm blow up but the difficulty I encountered wasn't becouse the kit was lacking, but more because of the shape and method of construction of the originals. I guess the originals were beaten from wrought iron by blacksmiths (Bessimer converters didn't appear until the 1870s, so no cheap steel in large quantities) and the designs are very reminiscient of a (horse and) cart. The tank sides are made of sections of wrought iron sheets, joggled at the ends and riveted together (no TIG!)

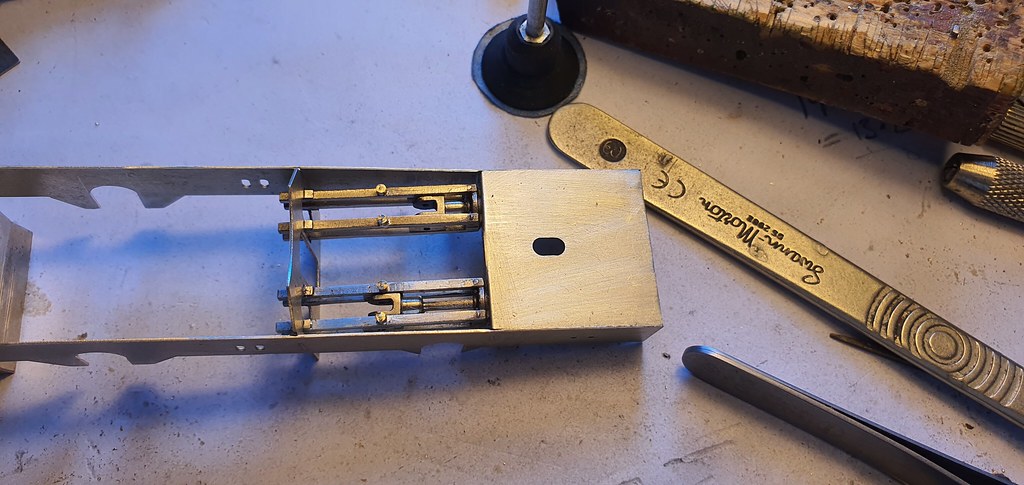

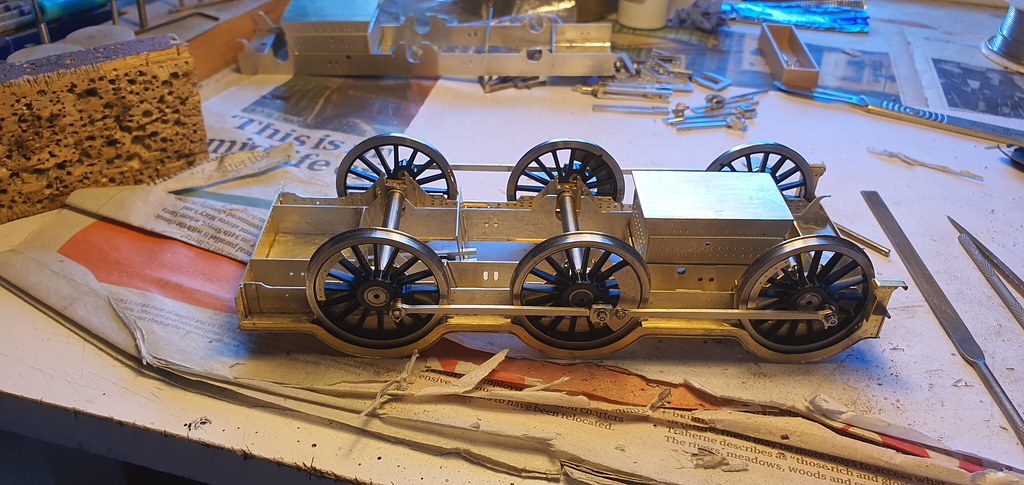

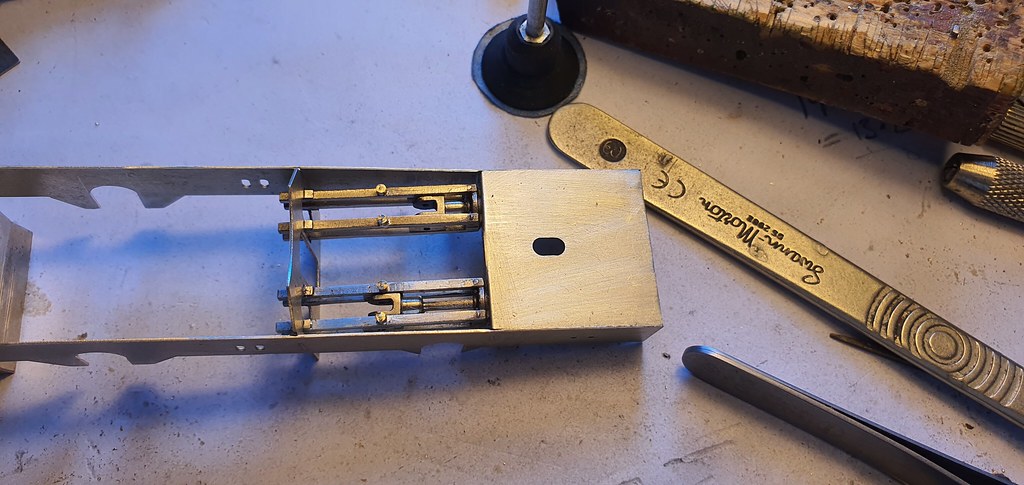

The first problem I encountered was the lack of an inner chassis. This is of course a 7mm peculiarity, we use wheels without outside bearings to simplify tender builds. I decided it would/might be fun to build a Finney style rocking beam inner chassis. I saw that BGS track standards are more like S7 than FS so compensation may be key. I think the tenders turned out OK, there's a lot of etches to fabricate parts that may have been better as castings (yikes if you're making the 4mm version!) but it goes together ok with a bit of care.

There's more photos on my Flickr page here nick dunhill

The next part of the job was building a test track, as Peco haven't ventured into the niche area of BG. I mithered Paul Scott (very modest man who is at least as good as Norman Soloman) and Richard Spoors for help and took my first plunge into trackbuilding of any kind. Tony Geary was kind enough to send me some simple Templots (and a bucketful of encouragement) which I stuck to a laminate board. I built half track, outside rail first (thanks Richard,) then laid the inside rail using a BGS track gauge. It ain't going to win any prizes for the best looking track ever but it seems to be ok. The rail is BGS bridge rail.

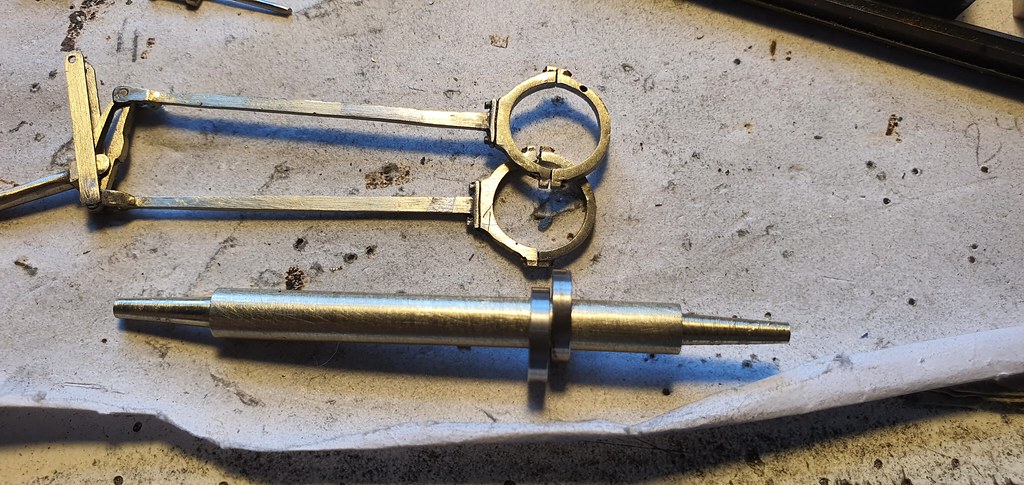

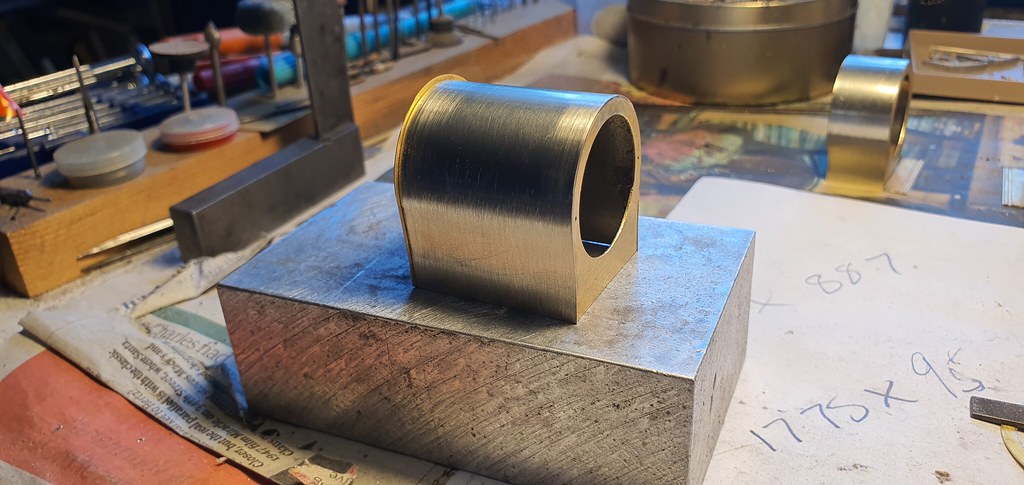

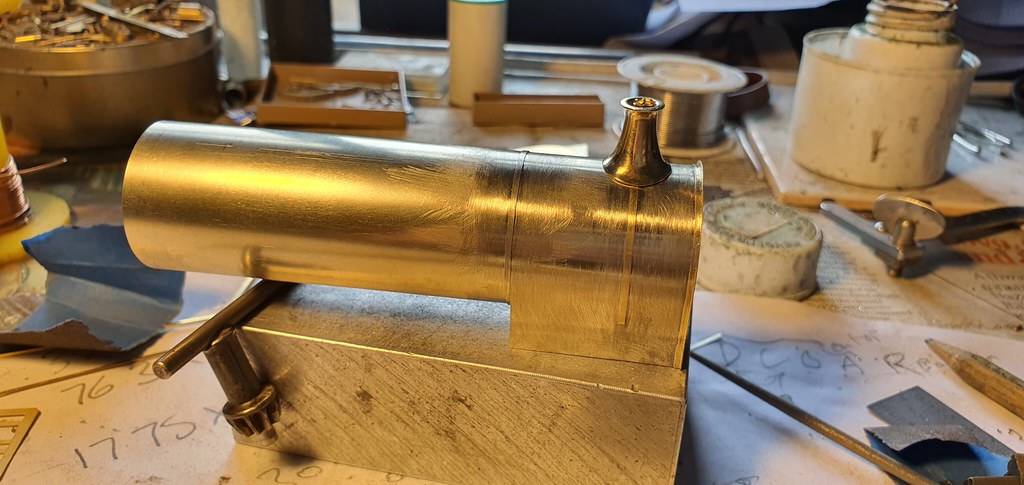

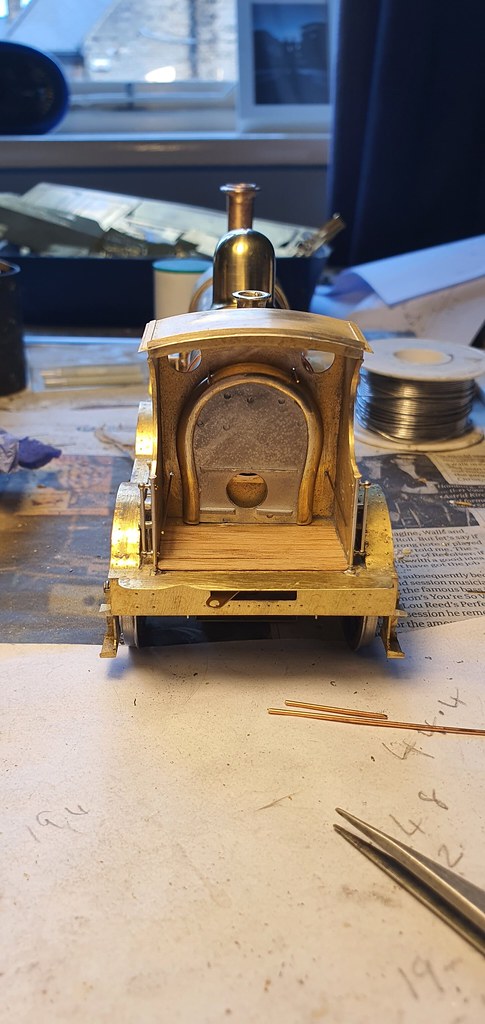

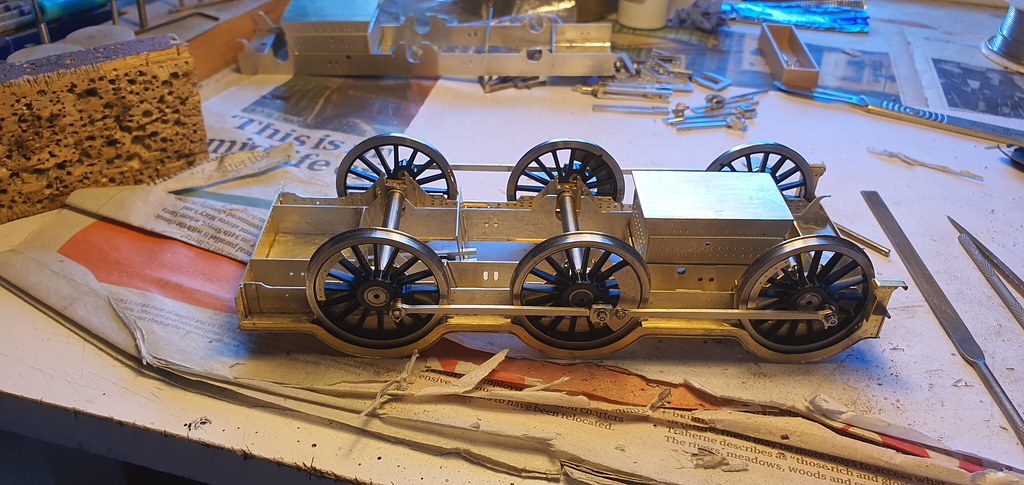

Then onto the locos. I built a Scorpio Queen last year and was very pleased with the kit. I assumed that this one would be of a similar quality, and so far it is. It has a million etches (or so) for all the various versions. The outer splashers for the BG version are feindishly difficult to form. The valances have to match the radius of the tyres of the wheels. It took ages! The kit is designed with a rocking beam compensation system which I didn't like the look of for coupled wheels. I decided to convert the dummy outside bearings to be the working ones, and leave the inner chassis as a dummy. This left me free to make a proper ashpan to hide the motor and fill with balast. It was quite tricky to modify cast dummy horn blocks to work effectively, but I lucked-out and the 3/16'' ID K&S tube I earmarked as bushes for the axles had an OD that was the same diameter as the horn cheek spacings in the outer chassis. I let short lengths of the tube into the dummy horn blocks and all worked fine. I made crude suspension from phosphour bronze wire and added pick-ups.

Currently I'm fettling Laurie Griffin inside motion parts. I'm copying the dimensions off the dummy cast set provided in the kit, what could possibly go wrong with that?

The tender kits from the Broad Gauge society are ok. They are a 4mm blow up but the difficulty I encountered wasn't becouse the kit was lacking, but more because of the shape and method of construction of the originals. I guess the originals were beaten from wrought iron by blacksmiths (Bessimer converters didn't appear until the 1870s, so no cheap steel in large quantities) and the designs are very reminiscient of a (horse and) cart. The tank sides are made of sections of wrought iron sheets, joggled at the ends and riveted together (no TIG!)

The first problem I encountered was the lack of an inner chassis. This is of course a 7mm peculiarity, we use wheels without outside bearings to simplify tender builds. I decided it would/might be fun to build a Finney style rocking beam inner chassis. I saw that BGS track standards are more like S7 than FS so compensation may be key. I think the tenders turned out OK, there's a lot of etches to fabricate parts that may have been better as castings (yikes if you're making the 4mm version!) but it goes together ok with a bit of care.

There's more photos on my Flickr page here nick dunhill

The next part of the job was building a test track, as Peco haven't ventured into the niche area of BG. I mithered Paul Scott (very modest man who is at least as good as Norman Soloman) and Richard Spoors for help and took my first plunge into trackbuilding of any kind. Tony Geary was kind enough to send me some simple Templots (and a bucketful of encouragement) which I stuck to a laminate board. I built half track, outside rail first (thanks Richard,) then laid the inside rail using a BGS track gauge. It ain't going to win any prizes for the best looking track ever but it seems to be ok. The rail is BGS bridge rail.

Then onto the locos. I built a Scorpio Queen last year and was very pleased with the kit. I assumed that this one would be of a similar quality, and so far it is. It has a million etches (or so) for all the various versions. The outer splashers for the BG version are feindishly difficult to form. The valances have to match the radius of the tyres of the wheels. It took ages! The kit is designed with a rocking beam compensation system which I didn't like the look of for coupled wheels. I decided to convert the dummy outside bearings to be the working ones, and leave the inner chassis as a dummy. This left me free to make a proper ashpan to hide the motor and fill with balast. It was quite tricky to modify cast dummy horn blocks to work effectively, but I lucked-out and the 3/16'' ID K&S tube I earmarked as bushes for the axles had an OD that was the same diameter as the horn cheek spacings in the outer chassis. I let short lengths of the tube into the dummy horn blocks and all worked fine. I made crude suspension from phosphour bronze wire and added pick-ups.

Currently I'm fettling Laurie Griffin inside motion parts. I'm copying the dimensions off the dummy cast set provided in the kit, what could possibly go wrong with that?

Last edited:

.

.