michael mott

Western Thunderer

I want to keep the Drawing thread and the loco builds separate, so my interest in the little shunting engines began many moons ago (2005) when I converted a Bachmann Percy into a rough representation of one of the Horwich shunting locos I called it Mercury.

I used the nominal scale of 1/24 for the build and of course the track gauge was 16.5mm.

Taking Percy apart.

Blocking up the loco with some Rigid PVC, and a turned brass dome, and chimney, this was the final version of plastic bits.

Placing styrene wrapper with embossed rivet detail.

A lick of paint over the plastic and the wheels have had styrene discs glued on .

Fancy brass bits added to the loco to spiff it up a bit, the nameplates are embossed annealed .003" brass made by using a 9H pencil suitably sharpened so as not to puncture the soft sheet. the sheet was placed on some archival quality matt board and I practiced before hand writing in reverse by printing it up and tracing over it enough times to get a decent enough result before working on the actual brass one.

Bertrand had asked for some coal for the firebox, so I had to oblige him.

Bertrand was rather fussy always polishing and dusting as the work progressed.

Beginnings of the brake set up.

Drivers View.

It is a charming little loco and one that makes me smile when i think about the fun I had building it.

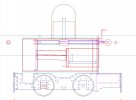

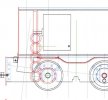

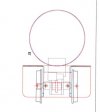

Next I purchased the drawings from the NRM and started to build a live steam version that would run on 45mm gauge track, so in order for the 45mm to represent 18 inches I decided to begin the model in 30mm to the foot scale, The dreaded conflation of different measuring systems. I mostly used Corel Draw 11 so that I could trace the digital copies I had purchased from NRM for the model and set it up to the 30mm scale. My Autocad Lt 2000 cannot import the drawings without crashing.

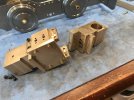

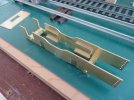

The chassis to this point was a few months with of work, with a number of part made and remade.

The plan was to use a large copper T for the boiler.

I was relying on the designs of Harvey Watkins for the boiler design and wanted to fire the loco with coal.

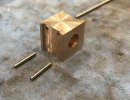

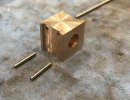

The wheel bearings are split as per the full size practice.

That's it for now, This is leading up to the new build which will be 1/16 scale or 3/4 inch to the foot . which will give a gauge of 1 1/8th inches.

Michael

I used the nominal scale of 1/24 for the build and of course the track gauge was 16.5mm.

Taking Percy apart.

Blocking up the loco with some Rigid PVC, and a turned brass dome, and chimney, this was the final version of plastic bits.

Placing styrene wrapper with embossed rivet detail.

A lick of paint over the plastic and the wheels have had styrene discs glued on .

Fancy brass bits added to the loco to spiff it up a bit, the nameplates are embossed annealed .003" brass made by using a 9H pencil suitably sharpened so as not to puncture the soft sheet. the sheet was placed on some archival quality matt board and I practiced before hand writing in reverse by printing it up and tracing over it enough times to get a decent enough result before working on the actual brass one.

Bertrand had asked for some coal for the firebox, so I had to oblige him.

Bertrand was rather fussy always polishing and dusting as the work progressed.

Beginnings of the brake set up.

Drivers View.

It is a charming little loco and one that makes me smile when i think about the fun I had building it.

Next I purchased the drawings from the NRM and started to build a live steam version that would run on 45mm gauge track, so in order for the 45mm to represent 18 inches I decided to begin the model in 30mm to the foot scale, The dreaded conflation of different measuring systems. I mostly used Corel Draw 11 so that I could trace the digital copies I had purchased from NRM for the model and set it up to the 30mm scale. My Autocad Lt 2000 cannot import the drawings without crashing.

The chassis to this point was a few months with of work, with a number of part made and remade.

The plan was to use a large copper T for the boiler.

I was relying on the designs of Harvey Watkins for the boiler design and wanted to fire the loco with coal.

The wheel bearings are split as per the full size practice.

That's it for now, This is leading up to the new build which will be 1/16 scale or 3/4 inch to the foot . which will give a gauge of 1 1/8th inches.

Michael