You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathes and M/C tools.

- Thread starter OzzyO

- Start date

Rob Pulham

Western Thunderer

Will do, I will hopefully start it later today.Hello Rob, all,

please do put a thread on here. When you do drop me a line so I'll know where to look.

ATB

OzzyO.

OzzyO

Western Thunderer

Hello all,

not that much to say at the moment as I'm waiting for materials.

So I've been drawing the mounting plate for the reading head on the Z axis. This is where it will fit, It looks like the scale is out but it's just parallax? error the scale is within one or two Thou over 12".

Measuring for the plate it's going to be 3" high and 23/4" wide by 1/4" thick. I'm going to have to remove 5/32" from most of the bottom to account for the step for the ring.

You can see where the step is on the top of the mounting ring. the clamps in place to see where the cover for the scale will fit.

The cover clamped in place.

As luck has it there are two M5 holes that just need a tap running through them and I can use them to mark the centres of the M4 holes for the fixing screws.

After turning the big aluminium job I decided to get some tips that are for aluminium and non-ferrous metals. These cut the shim tubes absolutely brilliantly.

After all the testing for the cover for the Z scale I'm not going to fit it. Just for a bit of fun. Why?

ATB

OzzyO.

not that much to say at the moment as I'm waiting for materials.

So I've been drawing the mounting plate for the reading head on the Z axis. This is where it will fit, It looks like the scale is out but it's just parallax? error the scale is within one or two Thou over 12".

Measuring for the plate it's going to be 3" high and 23/4" wide by 1/4" thick. I'm going to have to remove 5/32" from most of the bottom to account for the step for the ring.

You can see where the step is on the top of the mounting ring. the clamps in place to see where the cover for the scale will fit.

The cover clamped in place.

As luck has it there are two M5 holes that just need a tap running through them and I can use them to mark the centres of the M4 holes for the fixing screws.

After turning the big aluminium job I decided to get some tips that are for aluminium and non-ferrous metals. These cut the shim tubes absolutely brilliantly.

After all the testing for the cover for the Z scale I'm not going to fit it. Just for a bit of fun. Why?

ATB

OzzyO.

OzzyO

Western Thunderer

Hello all,

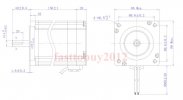

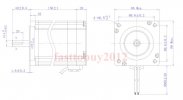

after I get the DROs fitted to the mill I'm thinking about fitting a stepper motor to the mill a) to decrease the low end speed and b) increase the top end speed. But I'm not sure what I'm going to need. This is the plate on the motor now.

This is the sort of motor I'm thinking about fitting.

One other thing it will do is reduce the weight that I have to move when the head is going up, on the head going down that is not a problem .

ATB

OzzyO.

after I get the DROs fitted to the mill I'm thinking about fitting a stepper motor to the mill a) to decrease the low end speed and b) increase the top end speed. But I'm not sure what I'm going to need. This is the plate on the motor now.

This is the sort of motor I'm thinking about fitting.

One other thing it will do is reduce the weight that I have to move when the head is going up, on the head going down that is not a problem .

ATB

OzzyO.

Rob Pulham

Western Thunderer

Yours looks a little more complicated to fit than mine was. I am feeling a bit under the weather so I will resume posting when I have more head space.

I note that your mill was made in the GDR, which reminded me of something that I read.

While looking for ideas to make my lathe more rigid. It may of course be an urban myth but I read that all the Chinese mini lathes. Which are sold in the west under various brand names, were originally from a design ripped off from someone/company in the GDR.

I note that your mill was made in the GDR, which reminded me of something that I read.

While looking for ideas to make my lathe more rigid. It may of course be an urban myth but I read that all the Chinese mini lathes. Which are sold in the west under various brand names, were originally from a design ripped off from someone/company in the GDR.

michael080

Western Thunderer

I am not sure this is a stepper motor and I am quite sure you don't want to use one. Typically, they wont't run with more than 100-150rpm in the size range above and unfortunately, stepper motors have almost no torque at full speed. The motor above has only two wires, so I guess it will be a simple DC motor. That is preferable anyway, because you can simply apply a dc-voltage to let it run. Stepper motors need a special voltage pattern on their two coils to rotate.

Michael

Martin Shaw

Western Thunderer

Not a myth at all Rob, all Chinese made mini lathes have their design origins in the Emco Unimat. Emco had the Unimat 4 made in China and inevitably it was copied, initially pretty badly but for a lot less money. The outcome was blatantly obvious, the customer preferred to pay less and accept the lower standards and Emco stopped making hobby machines.

Martin

Martin

I had one of the BFE stand alone milling m/cs but i could not really feel very comfortable with it,the lead screws were RH thread which meant that when you turned the handwheels clockwise,the tables came towards you instead of away from you which is normal engineering practice and the darned thing was metric.I bought it in the 1970s,eventually changed it for a Warco vertical mill some years ago,imperial and normal.

Ray.

Ray.