Heather Kay

Western Thunderer

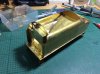

Nearly two days just cleaning up castings and etches. I tend to be pedantic about mould marks, and to be fair most of the brass castings in this kit are pretty good, but still…

Progress is glacial. While the frames are almost ready to erect, I wanted to get most of the detail castings that go on or around it sorted out. So, files, broaches, drills, ankle-deep in filings. I felt the loco brake gear out to be a sub-assembly, as the SDK consists of up to nine castings.

And this is what you end up with. While not quite of Mickoo or Dikitriki levels of neatness, it'll do. At this stage, the pull rod leading to the brake yokes is left loose on the pivot. I don't know whether the supplied cast rod will be long enough to reach the yoke, or what angle it will take, so these parts may change later once I get to a point of fitting wheels.

I would like to thank @mickoo again, for his forensic detail walk around of the Stanier Jubilee. There are sufficient similarities between Jubs and the rebuilt Scots, especially under the running plate, that make his images invaluable. As an example, a shot of the loco brake cylinder and bracket really helped me understand how the pull rods went together. Although taking a different form on the Jubilee (or at least in this kit), it let the brain cell see how the model parts were designed to fit together despite the supplied drawing!

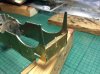

Progress is glacial. While the frames are almost ready to erect, I wanted to get most of the detail castings that go on or around it sorted out. So, files, broaches, drills, ankle-deep in filings. I felt the loco brake gear out to be a sub-assembly, as the SDK consists of up to nine castings.

And this is what you end up with. While not quite of Mickoo or Dikitriki levels of neatness, it'll do. At this stage, the pull rod leading to the brake yokes is left loose on the pivot. I don't know whether the supplied cast rod will be long enough to reach the yoke, or what angle it will take, so these parts may change later once I get to a point of fitting wheels.

I would like to thank @mickoo again, for his forensic detail walk around of the Stanier Jubilee. There are sufficient similarities between Jubs and the rebuilt Scots, especially under the running plate, that make his images invaluable. As an example, a shot of the loco brake cylinder and bracket really helped me understand how the pull rods went together. Although taking a different form on the Jubilee (or at least in this kit), it let the brain cell see how the model parts were designed to fit together despite the supplied drawing!