Steve Cook

Flying Squad

Its been nearly a year since I did anything on the Ruston, and although John D's christmas card didn't mention it this time round, thought I ought to get the etches out and carry on.

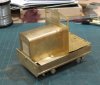

Nothing too exciting to report, the cosmetic axleboxes were built up from the etches supplied (3 per axle box) - a slightly fiddly job to keep them all aligned whilst soldering - then a quick passs with the file to get rid of the cusps. The footplate was removed from the brass sheet, rivets punched, then the lower edges folded back over themselves and soldered on. A couple of the rivets are very close to the bottom edge, so next time around I'll aim to punch them at the very edge of the half etched holes. The axleboxes were then soldered on, a quick tack joint from the rear, a sanity check to ensure they were lined up (there are half etched lines to help with this on the hidden side of the footplate), then soldered on properly. The sides were then folded down, the footplate resting on a piece of glass with a block of wood underneath to get the clearance for the front buffer beam riser.

The risers for the cab floor have been folded up in the shot above. The front buffer beam was cleaned up, two plates soldered on the rear for supporting the sandboxes and then the assembly soldered to the footplate.

Alas, a quick dry run on the chassis showed that the front sanding pipes I fitted now clash with the sandbox mounting plates - my fault, I deviated from the instructions and didn't double check That'll be tomorrows job then, removing the pipes and mounting them closer to the bottom of the chassis...

That'll be tomorrows job then, removing the pipes and mounting them closer to the bottom of the chassis...

Steve

Nothing too exciting to report, the cosmetic axleboxes were built up from the etches supplied (3 per axle box) - a slightly fiddly job to keep them all aligned whilst soldering - then a quick passs with the file to get rid of the cusps. The footplate was removed from the brass sheet, rivets punched, then the lower edges folded back over themselves and soldered on. A couple of the rivets are very close to the bottom edge, so next time around I'll aim to punch them at the very edge of the half etched holes. The axleboxes were then soldered on, a quick tack joint from the rear, a sanity check to ensure they were lined up (there are half etched lines to help with this on the hidden side of the footplate), then soldered on properly. The sides were then folded down, the footplate resting on a piece of glass with a block of wood underneath to get the clearance for the front buffer beam riser.

The risers for the cab floor have been folded up in the shot above. The front buffer beam was cleaned up, two plates soldered on the rear for supporting the sandboxes and then the assembly soldered to the footplate.

Alas, a quick dry run on the chassis showed that the front sanding pipes I fitted now clash with the sandbox mounting plates - my fault, I deviated from the instructions and didn't double check

That'll be tomorrows job then, removing the pipes and mounting them closer to the bottom of the chassis...

That'll be tomorrows job then, removing the pipes and mounting them closer to the bottom of the chassis...Steve

Unlike most of the other modelling scales who fix a scale and change the track gauge, Gauge 1 keeps the same track gauge and changes the scale. 1/32 is the correct scale / gauge ratio in the same vein as P4 or S7. It all comes under the Gauge 1 banner, you just model in either 10mm (1/30.5) or 3/8" (1/32 or 9.53mm:foot). Broad church you see...

Unlike most of the other modelling scales who fix a scale and change the track gauge, Gauge 1 keeps the same track gauge and changes the scale. 1/32 is the correct scale / gauge ratio in the same vein as P4 or S7. It all comes under the Gauge 1 banner, you just model in either 10mm (1/30.5) or 3/8" (1/32 or 9.53mm:foot). Broad church you see...

A bit of filing required to remove the evidence of the half etch lines on the underside of the bonnet, then I can read the next bit of the instructions...

A bit of filing required to remove the evidence of the half etch lines on the underside of the bonnet, then I can read the next bit of the instructions...

Two 150 mile round trips wasted.

Two 150 mile round trips wasted.