Overseer

Western Thunderer

S'pose not, they all go grey.I don't suppose they have a colour chart for weathering effects, do they?

They start out nice colours though.

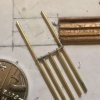

From the right - Southern Mahogany, River Red Gum, Red Ironbark, Blue Gum, Candlebark (not on NZR list), Red Stringybark, Grey Box, etc. Interesting that NZR used a lot of timber types which were not considered durable in Victoria.

The old timber is a 150 year old split shingle made from Mountain Ash, a sleeper would usually be a paler grey. Australian sleepers were not treated or creosoted, presumably NZ was the same with the imported timber.

- only the most basic of tools.

- only the most basic of tools.