Richard Gawler

Western Thunderer

My next project is a 4-wheel saloon coach from a kit by Connoisseur Models. This is my first attempt at building a coach kit. I have tried to modify RTR coaches e.g. cut and shut and even new sides on RTR in smaller scales, none with much with success so hopefully a purpose-made kit will work out better.

I am not sure whether my Heybridge Railway actually needs this coach. It might be there to supplement the brake coach for fair days and market days. I want to build the brake coach with fairly heavy modifications of the source kit so some practice will be good. If I don't want the saloon, or the layout just cannot be big enough to hold a two-coach train then I can treat it as a learning kit to sell on after completion.

The kit comes with a prerolled roof, good because I don't have any rolling bars and the roof is going to be conspicuous on the finished model.

I bought the kit at Kettering on 5th March, it is secondhand but unbuilt so a modest cost saving over buying a new one.

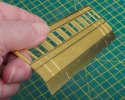

Work begins by forming the sides, beginners luck maybe but this these turned out pretty well.

I don't have any folding bars either so I formed the tops of the sides in the vice. There is a half-etched bend line and I scored this very heavily using a scriber, and then worked the flange over I suppose about 15 degrees at a time. This is not ideal because it tends to stretch the narrow strip of flange. Afterwards I worked the flange down onto a piece of plywood from an old drawer unit (nice square edge) and the ripples have pretty much vanished.

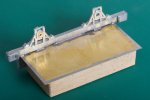

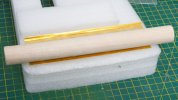

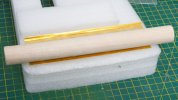

The newest additions to my armoury are an offcut of hardwood dowel and a piece of dense foam. This is the sort of shiny rigid foam which comes in blocks formed by layers bonded together. Anyway, I formed the turnunder by pressing the dowel into the side. I didn't roll the dowel very much. I doubt this approach would work on a mainline coach but on this one the results just came out perfect first time.

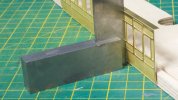

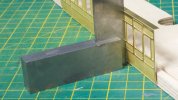

Working the fold for the flange at the bottom was more difficult than the turnunder but easier than the flange at the top. I am holding the flange flat onto the bench with the straight edge whilst lifting the side with the steel rule.

Part way round.

Bonus picture because I had a visitor and they held the camera. I am shoving the flange into place with the back of the square.

Result

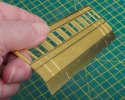

Hopefully this photo shows the shape created using the bit of dowel is actually pretty good.

Small thought:

When I was writing technical publications for a living we decided to exclude tools and body parts in photographs. The only exception being the use of a tool in an unconventional way e.g. using a using a screwdriver to prise off a blanking cap. Having a distant and impersonal look is fair enough for system build and maintenance manuals (and the only practical way if you want a consistent hand in the photos) but maybe it brings a bit of life to a workbench topic?

I am not sure whether my Heybridge Railway actually needs this coach. It might be there to supplement the brake coach for fair days and market days. I want to build the brake coach with fairly heavy modifications of the source kit so some practice will be good. If I don't want the saloon, or the layout just cannot be big enough to hold a two-coach train then I can treat it as a learning kit to sell on after completion.

The kit comes with a prerolled roof, good because I don't have any rolling bars and the roof is going to be conspicuous on the finished model.

I bought the kit at Kettering on 5th March, it is secondhand but unbuilt so a modest cost saving over buying a new one.

Work begins by forming the sides, beginners luck maybe but this these turned out pretty well.

I don't have any folding bars either so I formed the tops of the sides in the vice. There is a half-etched bend line and I scored this very heavily using a scriber, and then worked the flange over I suppose about 15 degrees at a time. This is not ideal because it tends to stretch the narrow strip of flange. Afterwards I worked the flange down onto a piece of plywood from an old drawer unit (nice square edge) and the ripples have pretty much vanished.

The newest additions to my armoury are an offcut of hardwood dowel and a piece of dense foam. This is the sort of shiny rigid foam which comes in blocks formed by layers bonded together. Anyway, I formed the turnunder by pressing the dowel into the side. I didn't roll the dowel very much. I doubt this approach would work on a mainline coach but on this one the results just came out perfect first time.

Working the fold for the flange at the bottom was more difficult than the turnunder but easier than the flange at the top. I am holding the flange flat onto the bench with the straight edge whilst lifting the side with the steel rule.

Part way round.

Bonus picture because I had a visitor and they held the camera. I am shoving the flange into place with the back of the square.

Result

Hopefully this photo shows the shape created using the bit of dowel is actually pretty good.

Small thought:

When I was writing technical publications for a living we decided to exclude tools and body parts in photographs. The only exception being the use of a tool in an unconventional way e.g. using a using a screwdriver to prise off a blanking cap. Having a distant and impersonal look is fair enough for system build and maintenance manuals (and the only practical way if you want a consistent hand in the photos) but maybe it brings a bit of life to a workbench topic?

Last edited:

. It's a bit late to get the torch out so I put a narrow bead of the epoxy along the inside of the gap. I used masking tape to keep this tidy.

. It's a bit late to get the torch out so I put a narrow bead of the epoxy along the inside of the gap. I used masking tape to keep this tidy.