I have had a go . . .

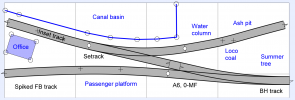

View attachment 211916

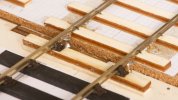

Two chairs came off, but for the rest I had to chop out the entire timbers.

View attachment 211920

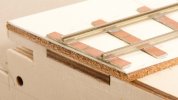

Then I drove in this peg (headless panel pin) to push the gauge out to 32 mm.

View attachment 211917

Tested with all of my locos and then rebuilt.

The headshunt is too short for the Y14, but its wheel sets do behave themselves at the blade tips. So fingers crossed for the time when I have a longer track attached, and the loco and its tender can both run clear of the turnout.

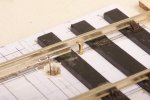

View attachment 211919

This is not too pretty. More distance from tiebar to baseboard joint would allow for a slower transition from 32 to 31.5 mm.

Some of the chairs were clearly stuck down forever. I have used up all of my plastic timbering and I will use plywood timbers in future. Simply because chairs can be adjusted so much more easily. I am so glad I am building this diorama as a learning project. Just imagine building a layout and making the same mistake many times over before realising.

For my future trackwork, I will happily use 0-MF at crossings and for inset track, but I will use 0-F for the heel ends of points and tighter curves. This leaves a decision for other plain trackwork . . . I reckon, neither standard will look better or worse, and neither will run better or worse at the low speeds of a light railway.