Richard Gawler

Western Thunderer

View attachment 188062

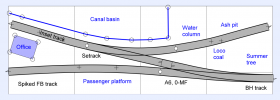

George @Herb Garden : The track plan is very is close to this, but I am showing a Peco curved point here in AnyRail to represent a mildly-curved A6 which I am using.

@adrian : The baseboard is from a standard G&H module. I placed the track on the board as carefully as I could and marked a line to show the rail nearest to the basin. Then I marked another line parallel to this and cut out the baseboard top to suit - see Dockside tracks. It was then easy to lay the cross members onto the top to mark them for cutting out. The construction sequence for the big bits was (with the structure upside down) top, three cross members, both ends, front and rear, basin base; and then trimmings like the back of the basin and the three diagonal braces.

@Yorkshire Dave : The operating practice on the Navigation was for sea-worthy vessels to tie alongside near Osea Island, where their loads were transferred to old Thames barges. These were towed across to the sea lock, moved into the basin, and everything was moved again this time onto barges. There is more in part 1 of my back story, this part of the story is factual. I will be very happy to make some passable looking water. Some kind of watercraft would be a bonus but it isn't a must have. Shoving all of this track into five square feet is probably a cliche in its own right, but if I can end up with a better test track and some experience of larger-scale scenics this will be good.

I have been pondering the scenic development of "Heybridge Basin". The track plan has been fixed since early June but some thought is needed to show this is "Essex" and not "in England". So, thinking about localisation, the ideas so far are the following:

Great Britain

- Sleepers 9 ft long, set at the usual British spacing with spiked FB rail

- Facing point lock on the passenger line

- Architecture item 1: platform shelter

- Navigation to look like a canal not a river

- Wildlife: mute swans in the basin

- Water column of GER pattern

- Large sky on the backscene

- Ballast: local sand and gravel (independent railway, so not GER ash from Stratford)

- Architecture 2: small office building from Paper Mill Lock, this is seven miles away on the Navigation

- Waterfront defined by stone slabs on brick walls, like the sides of the sea lock

- Early use of concrete for building blocks, pioneered by E H Bentall

- Station name board “Heybridge Basin” (!)

I have built, it seems, seventeen model railway layouts. Only four worked out really well, and these were the four where I planned the treatment of every square inch before I even laid the track. It makes sense really, especially if some more of the baseboard top has to be cut away. There is no rush, but I do think "Essex" deserves more than "ballast". This is the 1890s but I still await the first TOWIE remarks