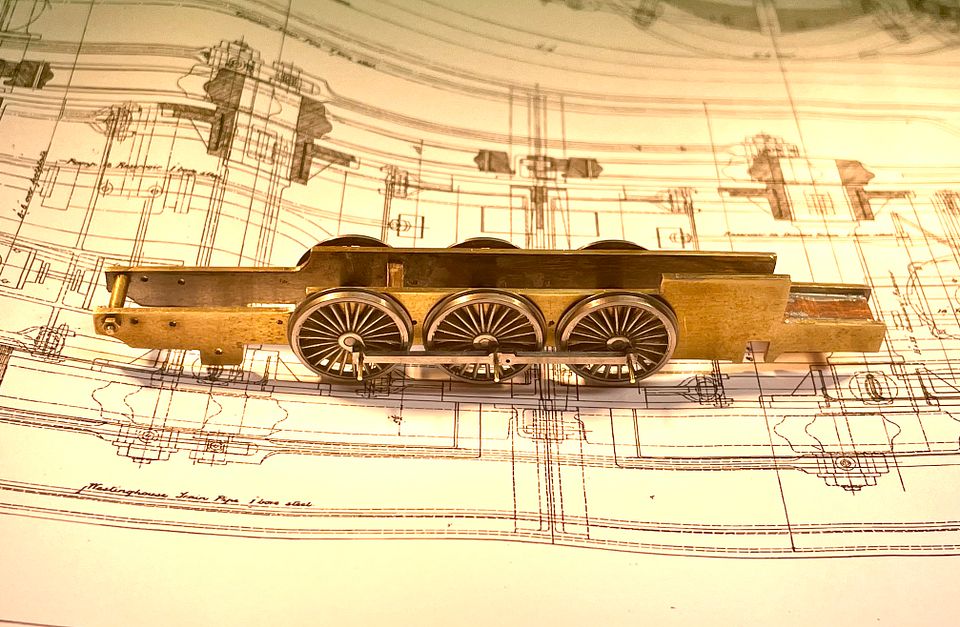

The next loco from the Darlington works in St Albans will be a Skittle Alley, AKA a Raven NER 4-6-2 No. 2400.

It will make a striking and exactly contemporaneous partner to Valour on CF. (Just needs someone to make a NER Dynamometer Car).

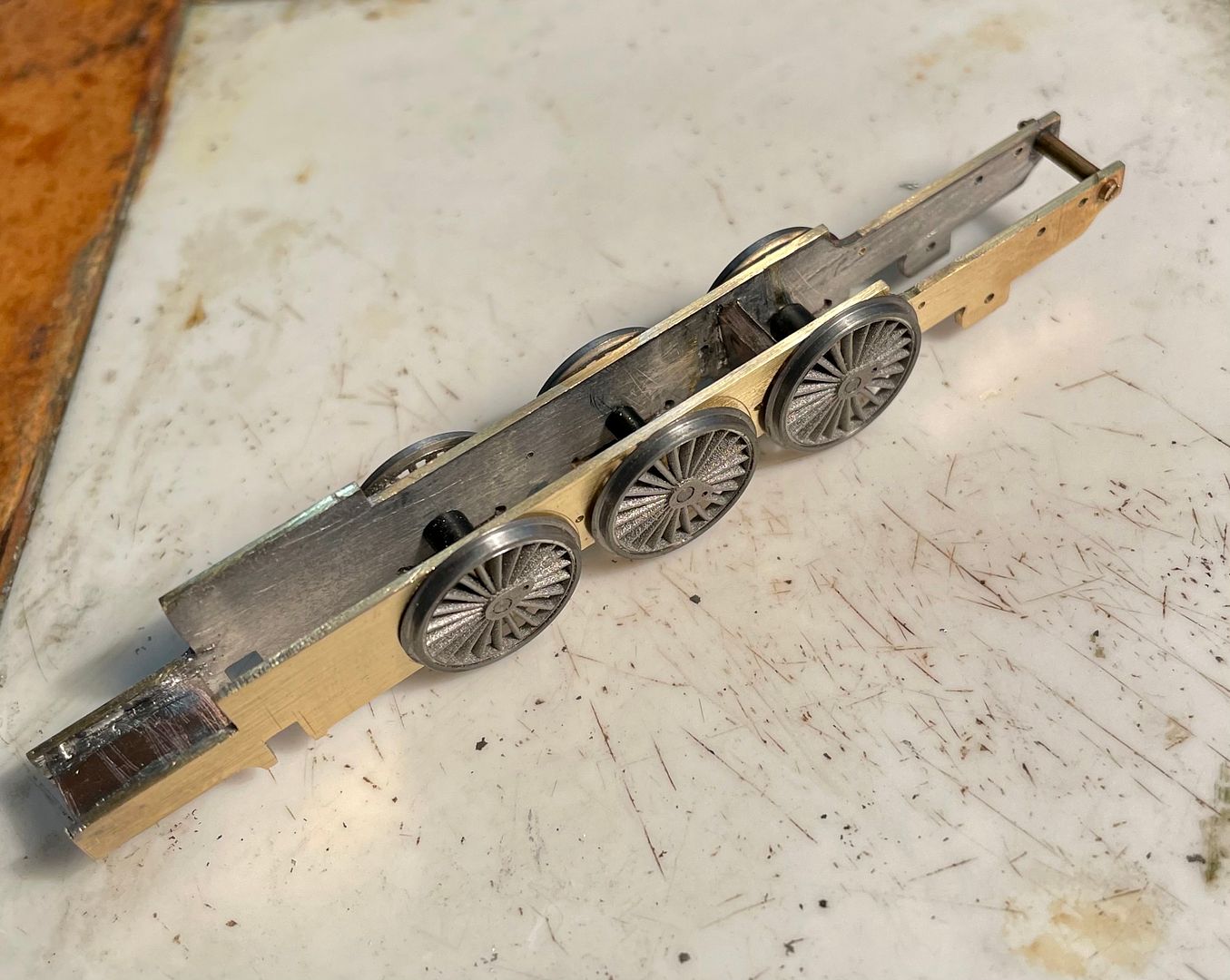

A holiday start was made on the tender, reduced from the original Steve Barnsfield artwork for Mick Simpson: many thanks to Mick and Chris Higgs for letting me have some etches.

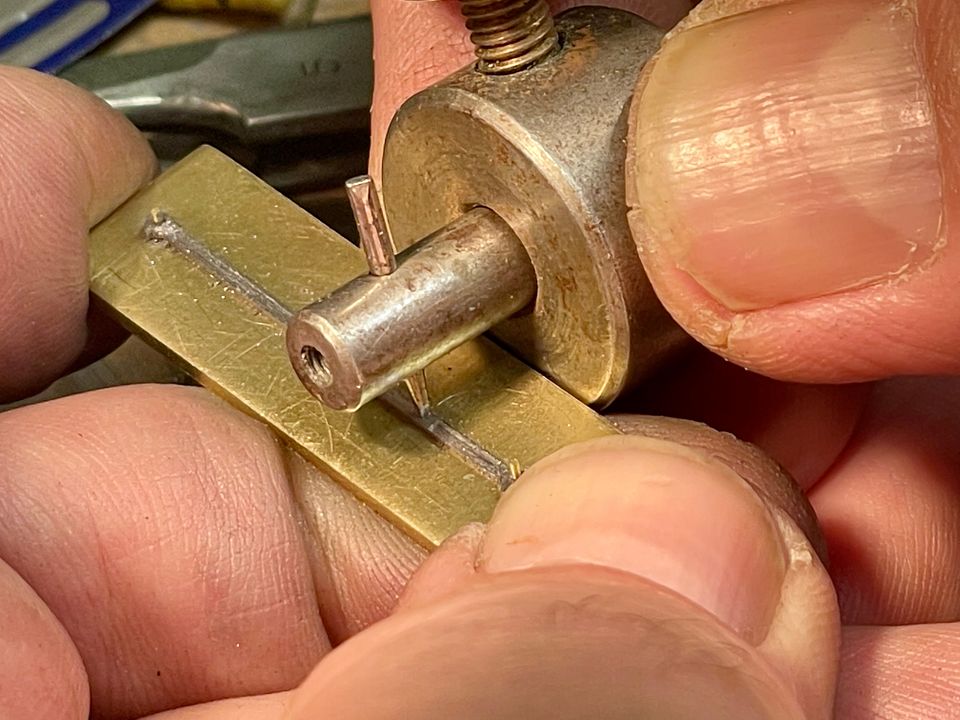

The fit of the parts is excellent and so the body work made good progress. The tank and bunker are made as two layers (I did re-do the sides as the first attempt wasn’t dead flat): the inner top flare section is half etched. This was swaged around a 1mm diameter rod held on top of the vice for the inner layer. The three smaller half-etched outer flares needed another method, however.

Rob Pulham has made one of these in 7mm scale, so I copied his excellent technique for forming the flares. This involved a 1mm diameter steel rod and some hard(ish) rubber sheet.

The rod and narrow flare component were carefully aligned in a vice and then squeezed hard.

This translates the curvature of the rod into the brass strip to make the flare, as can be seen in the photo with them as separate components.

It was straightforward to solder these to the tender sides.

The underframe sides and ends complete the work so far. The kit produces some nicely understated flares: it’s easy to make them too large in 2mm scale. Having said that, Bob Jones is making some full height coal side plates, as the kit design is too low.

Work on the engine should continue at Missenden Abbey very shortly…

Tim

repairoutlet.co.uk

repairoutlet.co.uk